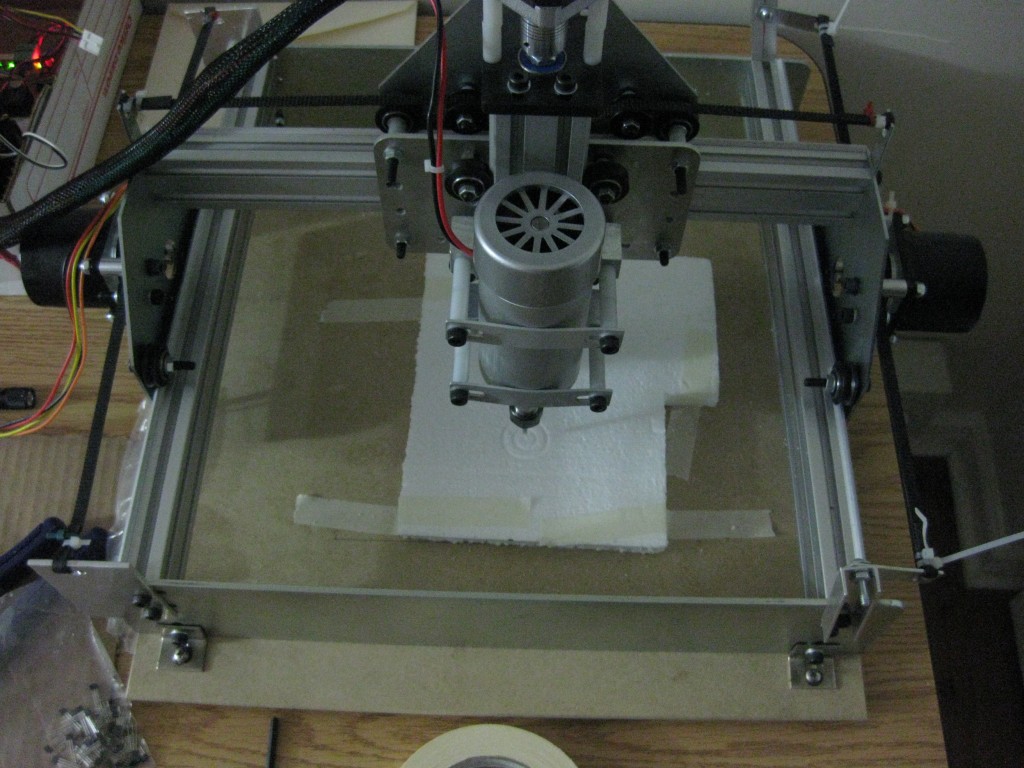

There was a problem with the Lab’s Makergear M2 recently that is worth writing up.

Last weekend, we had it off site for a demo event for a group of highschoolers interested in engineering and medicine, which included assembling samples of these printable articulated hands that Dr. Dietz designed. (Semi-related: I’ve watched him do it, and continue to be mystified how he does things like this in OpenSCAD). We printed some models live, but on the last print of the trip it made a burning plastic smell. Not the usual, pleasing corn-syurp-y PLA-at-work smell, but acrid recently-deceased-electronics smell. We couldn’t locate the problem, and everything was working, so we assumed filament impurity and moved on.

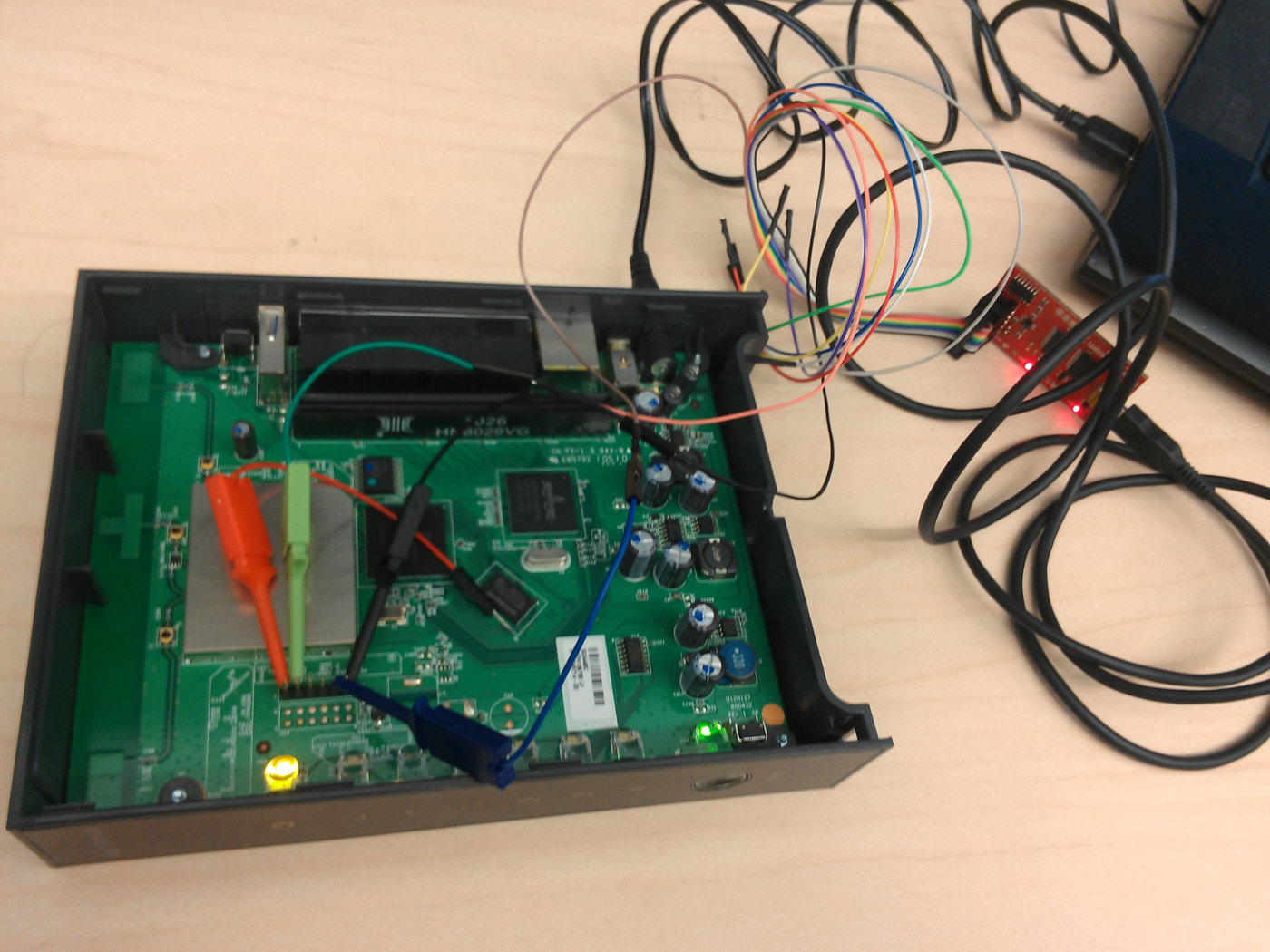

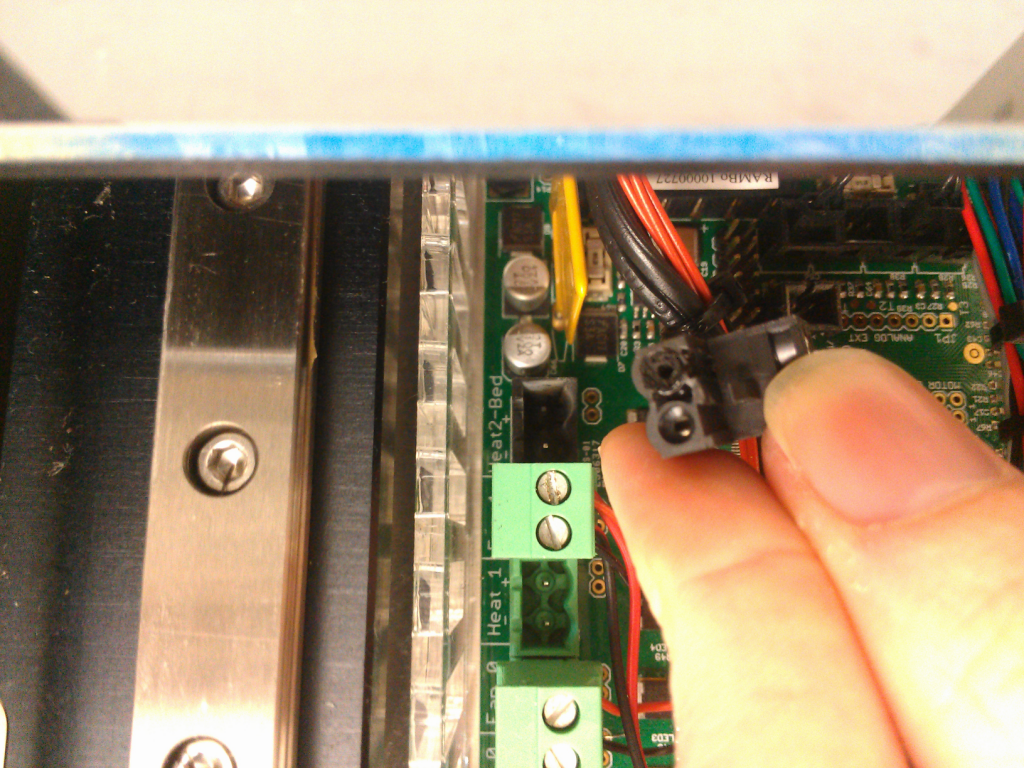

The next day, the bed stopped heating. Probing around with a DMM indicated the board was fine but the wire harness was not (A thank you to the Ultimachine folks for putting proper test points on the outputs). A bit of googling turned up this thread implicating the quick release screw terminal block that connects the bed leads to the board. Sure enough, upon yanking the connector free, the removable wire-side portion was a melted mass.

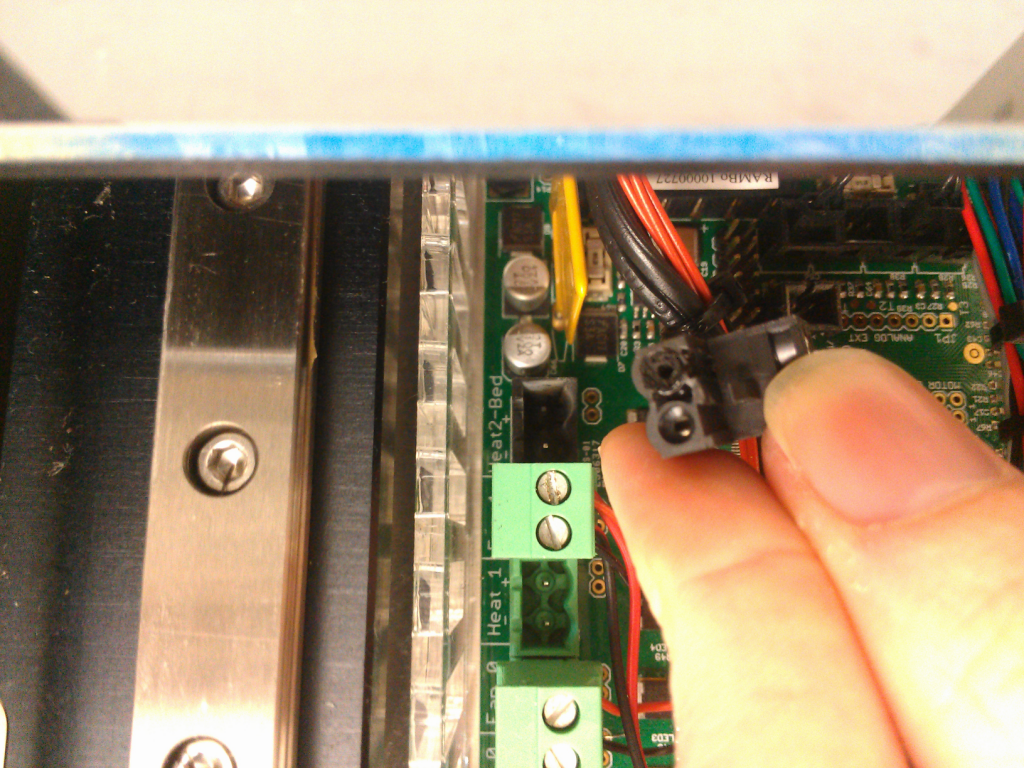

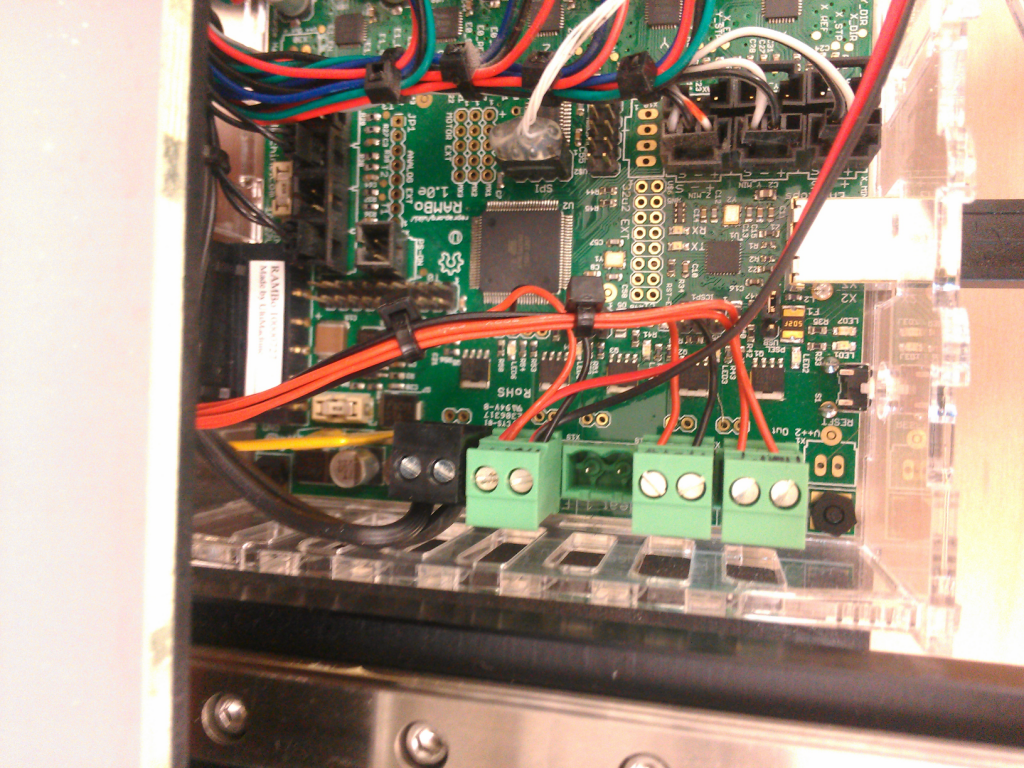

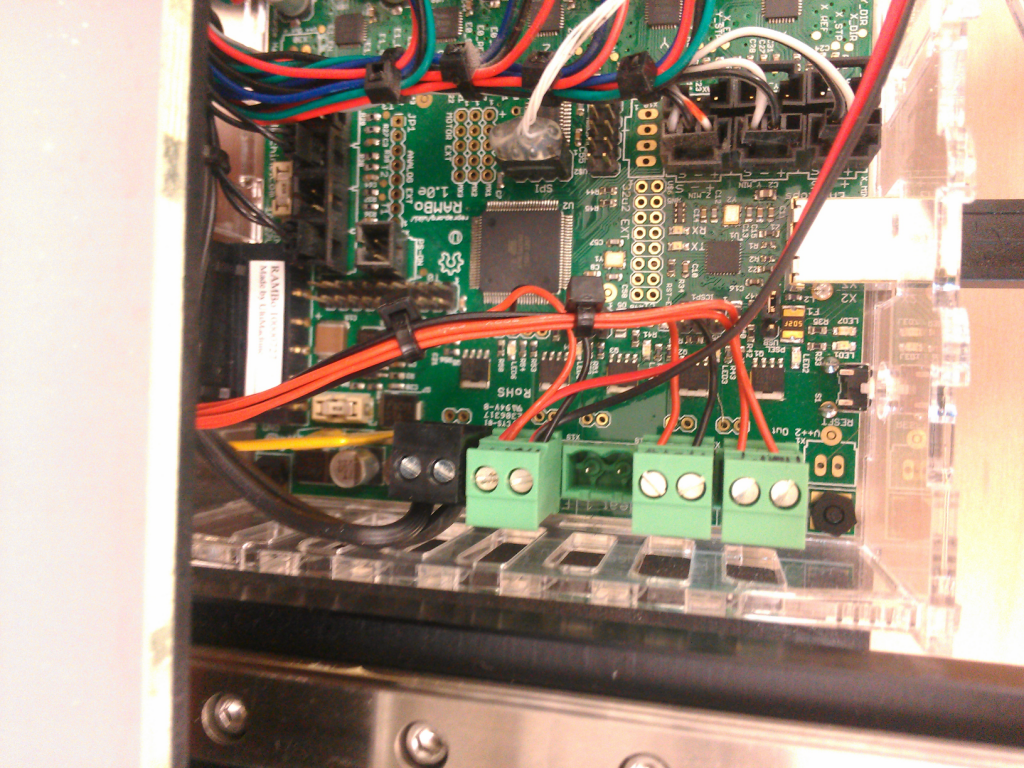

The existing connector is a Molex 39533-2002 rear-entry, two lead “Eurostyle” connector. Interestingly, Makergear and/or Ultimachine (Makergear buys and installs RAMBO Boards) used straight-through 5.08mm (200mil, but usually talked about in metric) quick release connectors – screws on the top, wires enter from the right – for the other MOSFET outputs, but a rear-entry (screws on the left, wires enter from the top) for the bed heat. This seemed odd since the side of the little laser-cut enclosure the RAMBO board lives in obscures the screw heads, but the reasoning will become clear. When I was poking at it to see if I could figure out what went wrong, I noticed the threads on the melted side were all but stripped out, but I don’t know if that was a cause or a symptom.

Since it is a standard connector, the (apparently intact) board side will mate with any two-position 3953x part. We found an ebay listing for five 39533-2002 for about $8 shipped, which are compatible and straight-through. Sadly, ebay is usually cheaper and faster than dealing with an electronics vendor if you only need one thing. The replacement seems to work fine, but clearly the original was a rear-entry model to keep the wires from being pressed against the side of the case. The M2’s wire harness is definitely its weak point; two of three serious intervention-requiring stoppages have been related to the bundle headed up to the bed/Y assembly.

The general lesson is to keep an eye on your screw terminals, especially if they are carrying current. I recall replacing the (non-quick-release) bed heater screw terminals on Collexion’s Makerbot ToM after a meltdown not long ago, so there is clearly a general issue with running that much current through screw terminals (several of the common crimped connectors would likely be superior in most ways). Since it came up (and since it is intuition-defying and I’ve heard a lot of people who should know better get it wrong) I’ll close with a reminder that you should not tin your wires before placing them in screw connectors – I know I’ve read this in a standard, research-backed source from ISO or NASA or somesuch, but I can’t find it right now.

ADDENDUM: It cooked two more of the same connector, then we discovered that the SD card connector was a little lose, and apparently causing a ground problem. It hasn’t cooked another connector since, and the bed heats faster than it was, so strong evidence that that was the root cause.