Some months ago I decided I wanted to play with an IBM Selectric typewriter, and after some fuckery, obtained and started working on an example of the dual-pitch, correcting Selectric II I find most appealing. At some point there will be an extended post about that, but 1. I’m not entirely sure I know what I’m talking about yet, and 2. Too much writing at the time I was working on it. This post is not about the machine, just the cover I made for it.

Selectrics are extremely fiddly machines, and some of the protective features to keep them in working order have not aged gracefully – the sound deadening, crud-deflecting foam layer under the keyboard, for example, has reverted to a petroleum-type substance in almost every extant example – so I wanted a decent cover to keep it in operable condition. They’re also rather large and awkwardly shaped, so a cover that looks OK sitting out is preferable.

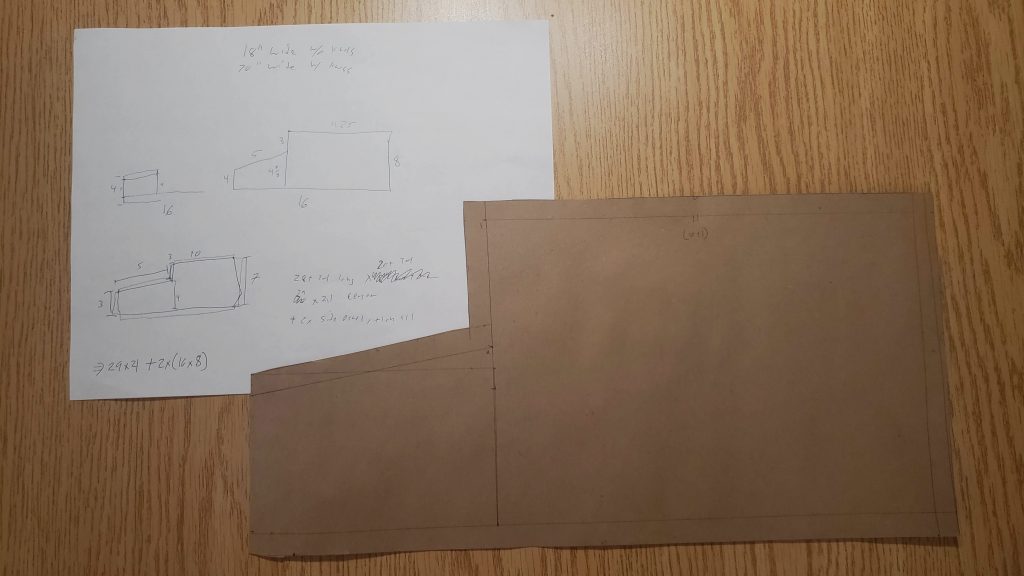

My Selectric has been sitting under a kraft paper cover for the last few months, but the intention was always that the kraft paper was a muslin for a quilted (well, pre-quilted fabric) cover, in part because I wanted a sewing project and my sewing machine was due for some exercise. So, I ordered a yard of cheap double sided pre-quilted fabric, a length of matching-ish bias tape, and went at it.

Measurements, paper pattern for side panels.

Plan + Parts

There was only one antique sewing machine related incident during the job, the feed dogs somehow managed to work their pair of hold-down screws out under the needle plate, but that was just a few moments with a screwdriver to re-fasten them when I noticed it wasn’t feeding.

Seams aren’t very even, but they are wrapped

Protected!

Reversible! – The shape is a little softer with the taped seams in.

Fits easily in one yard. Ends are traced from the paper pattern.

The finished product isn’t perfect from up close – largely because I was using it to teach myself how to use bias tape, and it shows that I had no idea what I was doing – but looks fine from a couple feet back, and does the job nicely. The little clearance along the back was totally intentional to allow the power cable to pass through, and not a transcription error.

The cover looks good. Did you use your antique White Rotary sewing machine? Thank you for posting an earlier article about working on this sewing machine. Your article had a link to the source for new carbon brushes for the motor at a very reasonable price. I work on fixing up older sewing machines, and this could be a valuable resource for other sewing machine motor brushes.

That was made on my Singer 201-2 (also discussed in several posts on here).