Since finally being rid of my PhD work, I’ve been hitting a bunch of projects that have been on my TODO list for ages.

The oldest so far is this PSU which has been sitting for …decades… in my parts pile with some compatible machines, and I’ve always intended to try rebuilding it. It died with a “ticking” symptom some time in the mid-00s.

I finally got around to it this week, and it wasn’t a bad job. About $10 of parts, a few hours of work, and it’s back in action. Rebuild details below.

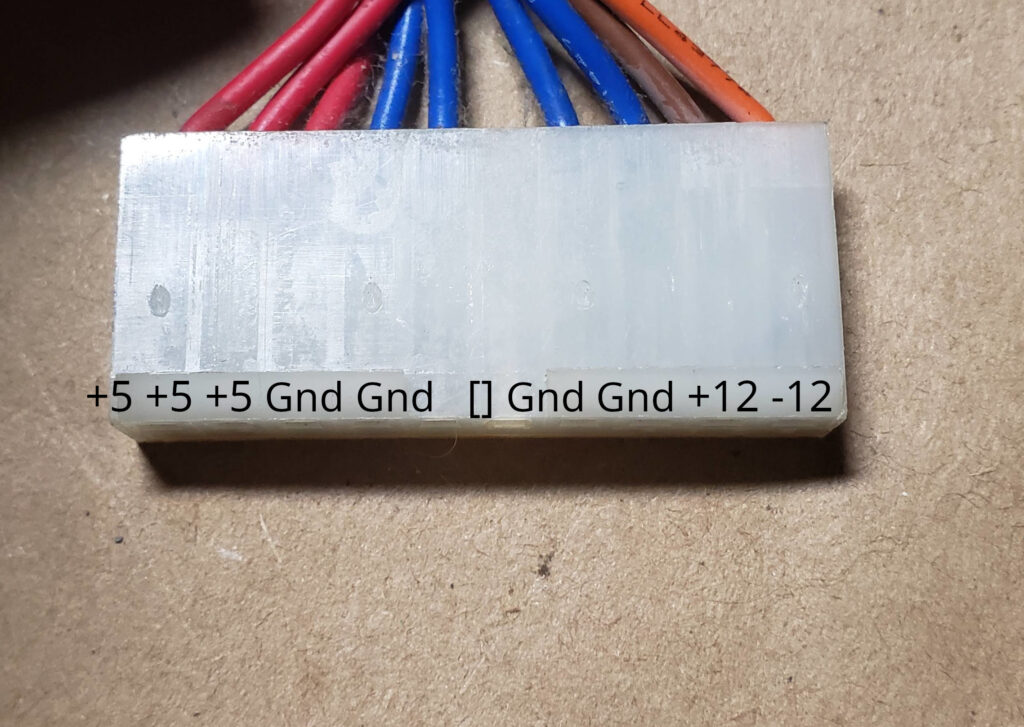

It appears that all the machines in that “standard desktop” chassis Apple used in the early 90s (Centris/Quadra 610, 660AV, Powermac 61000, etc.) use the same 86W power supply that offers +12V, +5V and -12V on the motherboard connector, plus two standard 4-pin Molexes. I have several such machines, and only had one working PSU.

It looks like it should be relatively straightforward to rig an alternative PSU for these if you had to – the connector appears to be a Molex KK936 family part (3.96mm pitch, single row 10 position, housing is Molex P/N 0026034101, you would also need female crimp ends). This reddit thread by brusaducj appears to confirm.

The DynaComp DCF-803 appears to be less common than the ASTEC AA16990 which was also shipped in the same systems. I also have one of those in working condition, it has not required a recap. The variants use slightly different wire colors (Who decided Brown for +12 was a good idea? The rest of the universe uses Yellow) but appear to be entirely interchangeable.

A year or so ago I set up a cart with all the required capacitors at Mouser that I … never got around to ordering because I got busy. A few weeks ago I needed some other parts and tossed the necessary capacitors in that order. Yesterday I finally spent a couple hours rebuilding and testing it.

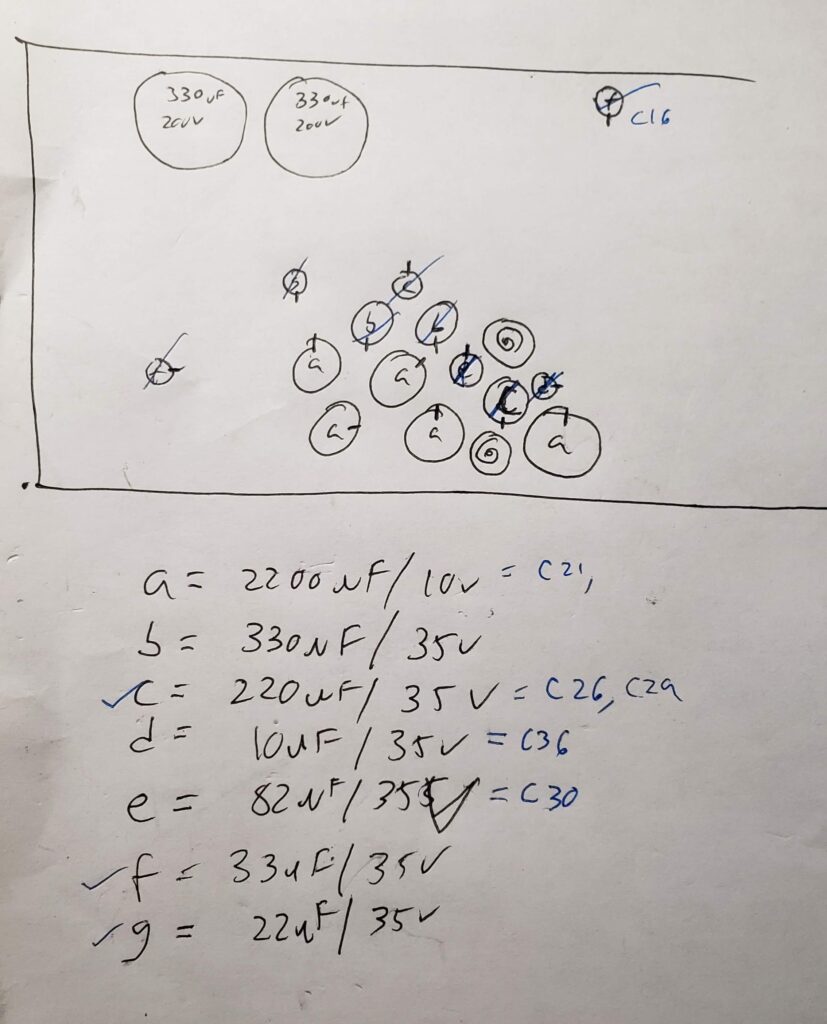

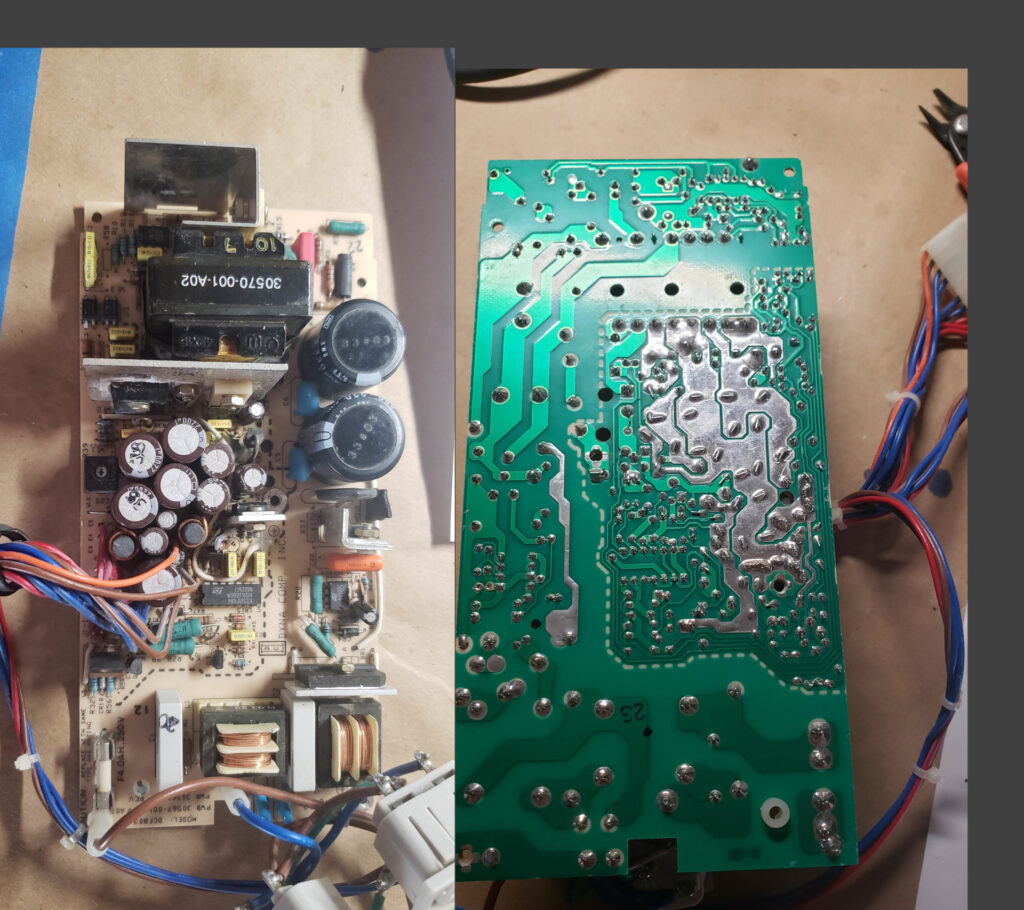

I based my cap order on this list from a badcaps.net forum thread and everything seems to check out; the rough locations and polarity notes I took while I was working are also shown below the list. I didn’t mess with any of the X/Y input caps, or the two big 330uF/220V tanks, they all seem fine.

(Qty) | Value | Height | Diameter | Lead Spacing | Price/each

Electrolytic 35V @ 85C Sp.

———————- — — —

(2) 33uF (SME) 11 5 3 $0.30

(1) 10uF (SME) 11 5 2 $0.43

Electrolytic 35V @ 105C

———————— — — —

(2) 220uF (LXF) 19 8 4 $0.47

(1) 22uF (KMF) 11 5 2 $0.28

(2) 330uF (LXF) 19 10 5 $0.47

(1) 82uF (LXF) 14 7 3 $0.38

(5) 2200uF (LXF) 24 13 5 $1.32

All dimensions in mm.

It only ended up being like $10 of parts (and almost the same in S&H – combine your parts orders) and a few hours of work (including disassembly, reassembly, and testing) to get it going.

A couple of the large pours are massive enough that they’re challenging to solder/de-solder – the iron I’ve been keeping on my desk is one of those Chinese “8586” hot air + iron units which only delivers about 50W on the iron, and that is barely enough. I’ve been using a JBC RMSE 3-tool station (which costs close to $6k) on campus and it’s making me covet fancier soldering gear; I’m probably too cheap for genuine JBC at home, but it looks like the nicer cheap options have leveled up again.

One of the Molex connectors was cut off on this PSU, and I have no memory of how that happened. I just soldered one cut off a dead ATX supply on; crimping a new connector didn’t seem like a good idea because it would have shortened the already short cable.

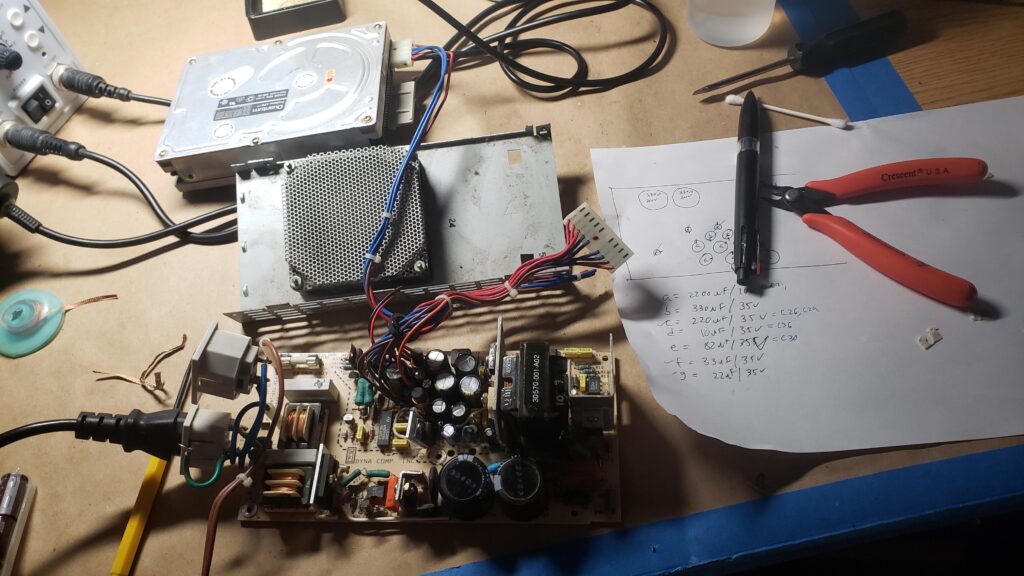

When testing, be aware that while it will try to start when switched on but disconnected, they do not stabilize unless loaded and will click in and out of reset. I ended up attaching an old SCSI HDD from the same pile for testing. The C13 power cable you see entering from the corner of the testing picture is both switched and surge protected, my hands were clear, and there is an electrical rated fire extinguisher on hand, but this is not a suggestion that this is a safe test procedure.

After repair and reassembly it happily boots my 6100, and I’ve now verified that neither my 610 nor 660AV’s motherboard is in good enough shape to run; the 610 smoked an already-visibly-degraded cap, and the 660AV is pulling the -12 rail to like -3, so there’s work to be done if I want to use either.