I’ve posted before on the slow restoration of my old 201-2 and its cabinet, last time I noted that my cabinet’s swing-arm wouldn’t auto-deploy, which prompted some discussions with other folks about the mechanism. One of those other pieces of input was someone kind enough to tip me off in the comments of my last note about this that there were a couple sets on ebay, which I looked at for details, then ended up buying one of for $22 shipped. I really only needed the lower pin and spring, but the spares are nice. This is what the seller pictured, and the light and camera are better than mine, so I’ll just use their picture, because it was well packed and exactly as described:

I now have mine working and have detail photos and measurements from the process that should make it easier for others to figure these things out. It’s actually a really simple mechanism, the following two pictures are pretty much all you need to know about how it goes together and works.

The pair of pins sit inside the rear leaf hinge. When the leaf is closed, the pins touch dome-to-dome, and pressure from the short pin (in the leaf) pushes the long pin into the little retention hole in the swing arm. When the leaf lifts, the spring under the long pin lifts it out of the retention hole, and the arm deploys.

The hack on mine to keep it closed without the lower pin was a simple flip of the support foot, from its normal outside-facing position to inside-facing in order to retain the arm when pushed in. I undid that, and obtained one absolutely-not-original washer and a jammed-in piece of plastic in the process.

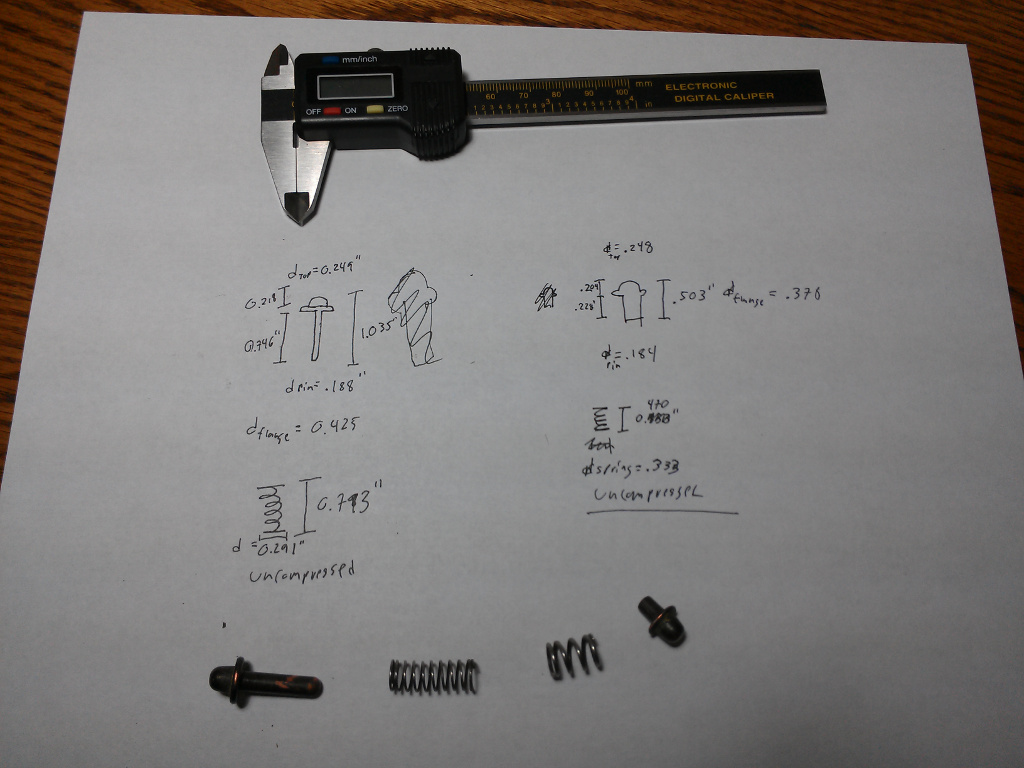

With a lathe (or hand tools and patience), photos, and measurements, I could probably have cloned the missing parts without much trouble, but there weren’t any details on the Internet. I’m now doing my part and fixing that:

One of these days I’m going to get good enough with a CAD tool to just bang technical drawings for this kind of thing out, but that is yet to happen.

Measurements:

|

Small Pin: OAL: 0.503″ Dome Length: 0.204″ Dome Diameter: 0.248″ Flange Diameter: 0.378″ Pin Length: 0.228″ Pin Diameter: 0.184″ |

Small Spring: OAL, Uncompressed: 0.470″ Diameter: 0.333″ |

|

Long Pin: OAL: 1.035″ Dome Length: 0.218″ Dome Diameter: 0.249″ Flange Diameter: 0.425″ Pin Length: 0.746″ Pin Diameter: 0.188″ |

Long Spring: OAL, Uncompressed: 0.793″ Diameter: 0.291″ |

I read to .001″ but the tolerances do NOT appear to be very close, even by ’40s standards, we’re talking sixteenths, not thou. It does appear to matter that the parts protruding through the hinges be rounded enough not to bind or gouge.

My existing swing-arm sagged enough to not auto-deploy, so I put the replacement on and… it also sagged enough to not auto deploy. Funny how 60+ years of spring tension and/or weight bearing does that to riveted joints. Fortunately, it appears the interference is just from the end of the arm rubbing against the inside of the recess it slots into when closed, so I did a little filing to smooth the underside of the recess out (not adequate to make it auto-open reliably), tried adding a little piece of sticky-backed felt to prevent rubbing (exacerbated the problem), and ended up solving that problem with… a piece of clear packing tape stuck where the arm rubs. The high quality, thick, glassy stuff. I should probably paint the spot with urethane or something, but the tape is on hand, reversible, and works great.

The arm doesn’t quite sit flush when retained by the pin, but I’m yet to snag anything on it, and having it auto-deploy is way better than having it sit flush.

Cool. Still not as cool as my mother’s White cabinet that uses a pulley and braided steel cord to lift the head when you open the leaf, but cool none the less.

Thank you!!

Now, any idea where/how to get those two missing parts (longer pin and screw) that I am also missing on my cabinet?

The options I’m aware of are either cutting them out of some brass stock with a lathe or getting lucky on ebay.

There are often auctions (1, 2 (no springs)) with subsets of the hardware turned up by permuting “singer” “42” and “cabinet” in the search terms.

I’ve heard that there are two slightly different versions of the arm assembly which are not fully compatible (different screw pattern), but the pins and screws should be compatible.

Ah, “permuting!” We programmers just used “parameters.” Does your word imply that the order in which the parameters are entered has importance?

Given how weird an unpredictable search engines have become as they get “smarter,” I wouldn’t be surprised if order mattered these days.

My “real” job is teaching computer engineering undergrads, which probably has something to do with my choice of language.

Thank you for this priceless information! I am currently restoring a #42 cabinet I found at a garage sale along the Texas border, and the arm won’t stay in because it is missing both pins and springs. I just found a set on Etsy & thanks to your post, I will be able to get the arm to stay in place.

Thank you for posting this. My husband and I are so frustrated wondering what the problem was with an arm we ordered for our art deco cabinet.

Hi! Thanks! I think this is exactly the problem that my cabinet has as well… I really appreciate you posting this information. Thanks again!

My machine desk just got refinished (beware, the legs were stained dark to match the veneer). My arm was deployed all the time and would not catch when the lid was shut to hold it in. I swapped the springs around, big spring to small dome that goes in lid, and now works like a charm.

I have this cabinet. The swingarm will not remain in place when the cabinet is closed–it stays out. It seems the retention pins aren’t doing their job. I’ve tried switching the springs on the pins. I’ve oiled the springs. NO luck. It seems that the pin that’s supposed to engage into the hole of the spring arm doesn’t reach it.

Any ideas?

Hmm… I’d look where the (longer) lower pin is supposed to be protruding out of the cabinet top to engage the arm, see if there is something blocking it from coming out or going in to the hole on the arm? Does your leaf sit flat when closed (ie. is the pin stack holding it up from closing fully?) I posted measurements for exactly this case, do your pin lengths seem similar?

Hi, My swing arm is not mounted in the cabinet. Do I need to take the top off to screw in the swing arm plate?

You shouldn’t need to. Most of the installation of the swing arm is from the bottom (Pull out the small drawer for more working room). The only part you might need to take off is the hinge on the leaf with the extra holes if you need to mess with the retention pins and springs.

Hello, this post is just what I needed to know about – except that I have every part except the arm itself! Are you able to please provide a rough measurement of the arm so I can figure out how to make a substitute?

Where can I purchase the metal swing arm itself. That is the only part I need.

I know this is an old post, but I’m wondering if you still have the “extra parts”? Specifically the long spring that attaches to the bracket. I’m in need of one, and will gladly pay you for it and shipping costs.

Sorry for not getting back to you for like … 2 months, end of semester grading rush followed by a vacation meant I never made it down the my parts box to check.

I do have a spare of the roughly 7/32″ O.D, 2″ Long (relaxed), 0.023″ wire extension spring that pulls the arm out from the hinge plate, and I’d happily send it to you for shipping, drop me a note at pappp@pappp.net if you’re still looking.

I’ll also note that 0.187 O.D. x .023 Wire Dia. 1-7/8 long springs with loop ends (or similar, a 0.180 OD would work, a 2″ would work, etc.) are common, and new ones can be had from most hardware suppliers for a couple bucks once you know the measurements.

This helped me so much, thank you!