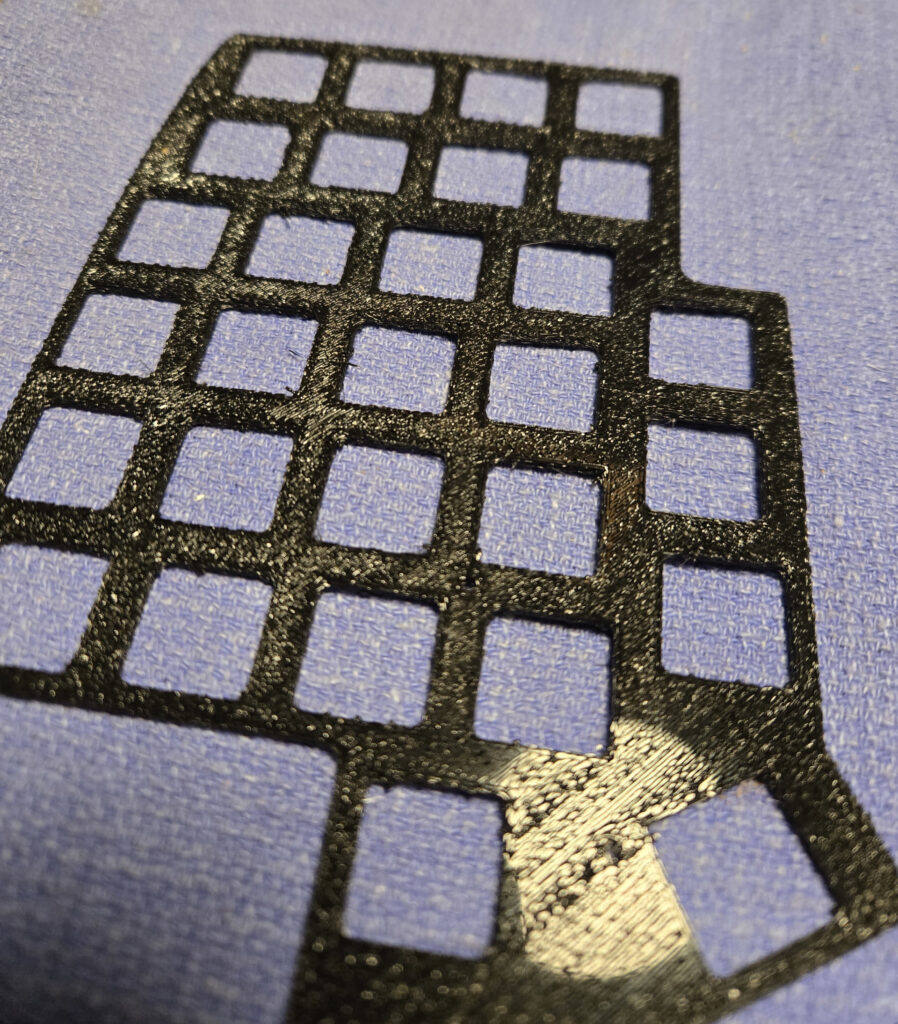

I’ve had a few projects recently that needed 3D printed parts, went to use a roll of black eSun PLA+ that I accidentally left out in my basement for some time, and it produced the telltale dull, rough, stringy, gappy print quality of hydrated filament.

Since I have some energy for projects right now, I decided it was finally time to get a filament dehydrator setup.

I went reading up about filament dehydration. The purpose-made filament dryers mostly seem to have a problem with actually removing moisture, most of them are dry boxes with no exhaust path, and the liberated water vapor has to go somewhere. Many seem to rely on instructions for the user to periodically open the lid during drying (which is …not automated), and a few contain a large amount of desiccant that will be more-hydrophilic than most filaments at drying temperatures, then itself require dehydration. Bambu seems to be doing basically the right thing with the AMS2 Pro and it’s automatic exhaust valve, but I’m not in the Bambu ecosystem and not looking to spend that kind of money.

So, instead, I looked at the DIY options. There are a variety of clever schemes with PID controllers and heating elements… but lot of folks seem to just repurpose inexpensive food dehydrators, and I went with a variation on that plan.

I picked up a $40 Elite Gourmet EFD770WD dehydrator; I paid a few extra bucks for a model with a digital thermostat/timer. It gets me a heater, a blower, and thermostatic control in a package that is at least theoretically safe for consumer use, which is really all that is called for.

There are many directions on the internet for cutting the grilles out of several trays on this style of dehydrator to make a spool-sized cavity, and many designs for large, elaborate, and almost inevitably multi-part printable extension tubes, which must be printed in a filament still rigid at the highest drying temperature you expect to need. The former seems wasteful and the latter seems like a tedious hassle.

I did something much lazier and made a tube out of foamcore. Just bent it using the little tabs for aligning the trays and taped. Mine is two pieces because none of my scrap pieces were quite large enough to do it in one.

The foamcore is slightly insulating which seems like a minor feature, and this method isn’t many hours of printing or destructive, which is a major feature.

I also saw several folks modifying a 3.5gal or 5gal paint bucket with a diameter around 12.5″, and I may try that in the future as a more polished solution, but didn’t have a suitable empty on hand.

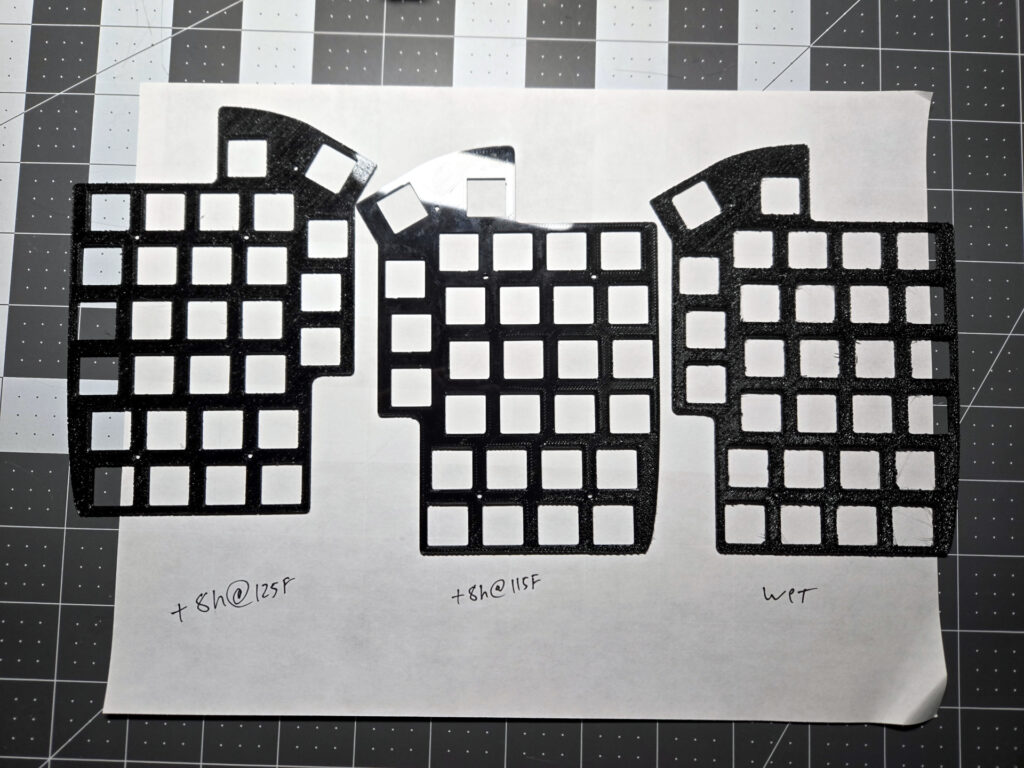

This particular dehydrator only lets you pick specific temperatures, but 115 and 125F are options right to either end of the suggested range for drying PLA variants. As for effectiveness, the main subject roll of black eSun PLA+ that sat out for a couple months, whose behavior is pictured above, went in for 8 hours at 115F, and initial results were really promising.

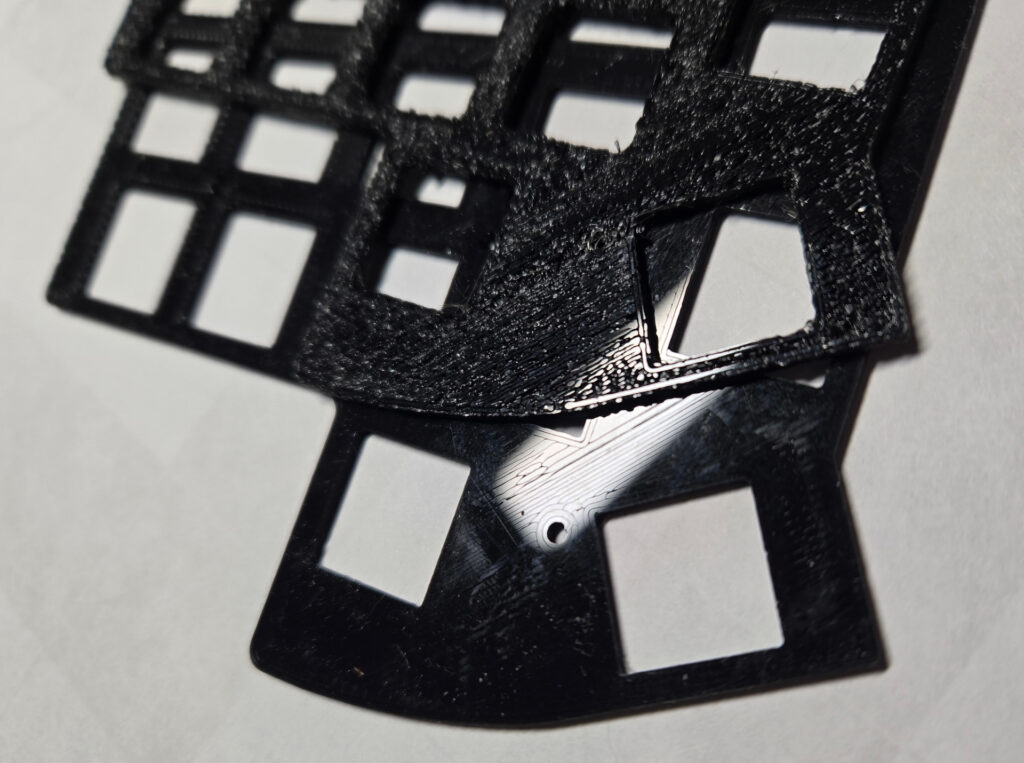

There were still some hydration-looking defects in areas (and the thermocouple I had shoved in through one of the lid slots of the dehydrator as a safety was reading a little low), so I gave it another 8 hours at 125F. And the results didn’t really change, but there was no obvious degradation. It has a dead spool producing parts that are usable if a little textured, which is worthwhile.

PLA+ is always a bit of a mystery material, I’ve generally supposed that much of it is doped with a couple percent PBT, but the relevant eSun PLA+ MSDS just shows 2-4% calcium carbonate (which apparently just provides nucleation sites to improve the crystallization) and 2-5% “other,” (likely pigment). CaCO3 isn’t very soluble in water, but who knows how it moved around or altered crystallization or whatnot during the wet-dry cycle. I ran some Inland “Egyptian Blue” regular PLA that had sat out in the basement for a while through a similar 8h@125F cycle and it did seem to reduce the surface irregularities (pips, especially on corners) between the previous and next part I printed in it, but not in such a dramatic way.

From a somewhat-amateur reading of the relevant literature, it seems like not all the hydration induced changes should be reversible. The most relevant thing I could find was Beyond Biodegradability of Poly(lactic acid): Physical and Chemical Stability in Humid Environments (2017) which looks at degradation due to liquid and vapor phase water infiltration, and found pretty substantial chemical changes especially from vapor at higher temperature.

The literature in general is a little spotty, there are more liquid phase studies (eg. ref), but studies like the earlier one comparing liquid and vapor phase water infiltration indicate they aren’t entirely comparable. The literature on drying is “thin,” and the relevant Internet content is thoroughly astroturfed by vendors trying to sell you gadgets (which is becoming a real problem in the 3D printing market in general; good luck finding un-sponsored information about anything). I’m sure some of the commercial (bio)plastic manufacturers/processors have detailed internal documentation, but they aren’t sharing.

In the same order as they dryer, I picked up some indicating desiccant packs to improve my ability to monitor and dry filament in bags. I’m so distrustful of Amazon junk now, I stuck one in the bathroom to absorb shower steam to see what the indicator hydration process looked like, and it is slowly turning pink after being repeatedly exposed to shower steam. Hopefully storing filament with known-dry desiccant will help keep it from going bad – at least as long as I continue avoiding any of the truly hydrophilic materials like Nylon that require special handling.

All in all: Hydration is absolutely a problem for PLA and adjacent materials, drying is imperfect but effective, slightly modified food dehydrators that exhaust the vapor do a fine job, and keeping material dry is better than trying to dry it.