Every now and then I like to post one of these, just to show process I currently use. The magic of 3D printing is that once you’re set up this kind of quick job comes up all the time.

I have this cheap thread assortment that came on tubes rather than spools. It’s surprisingly decent thread, has good coverage for finding suitable colors for any project… and the 13mm ID tubes wobble badly on standard 4.5x40mm spool pins on sewing machines, especially when filling bobbins.

I was doing a little (ham fisted) machine sewing this weekend and it was irritating me …so I fixed it.

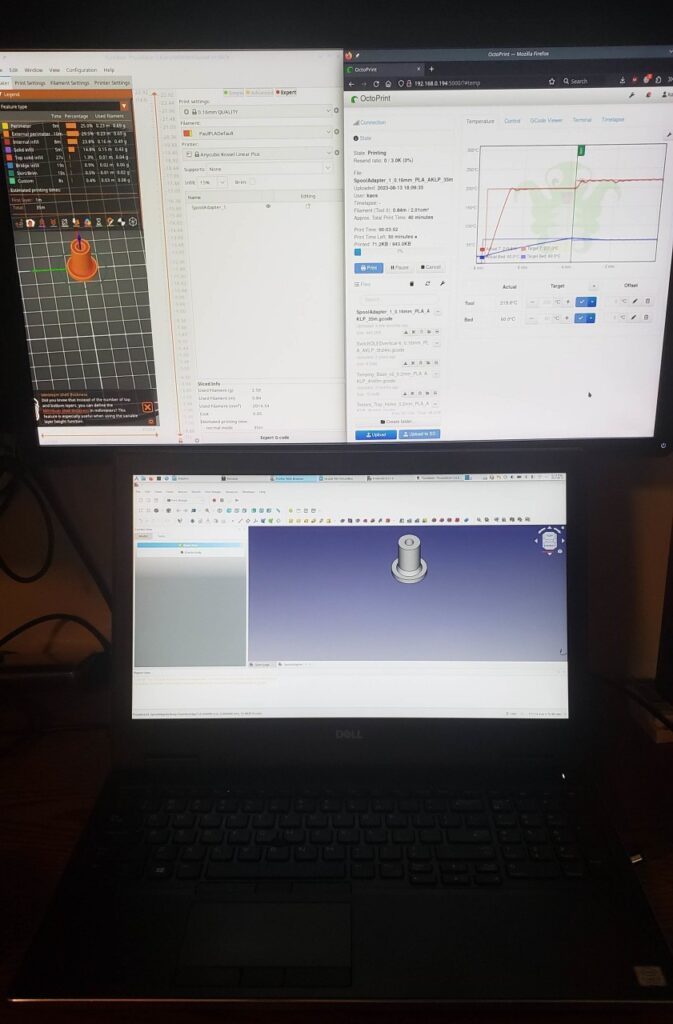

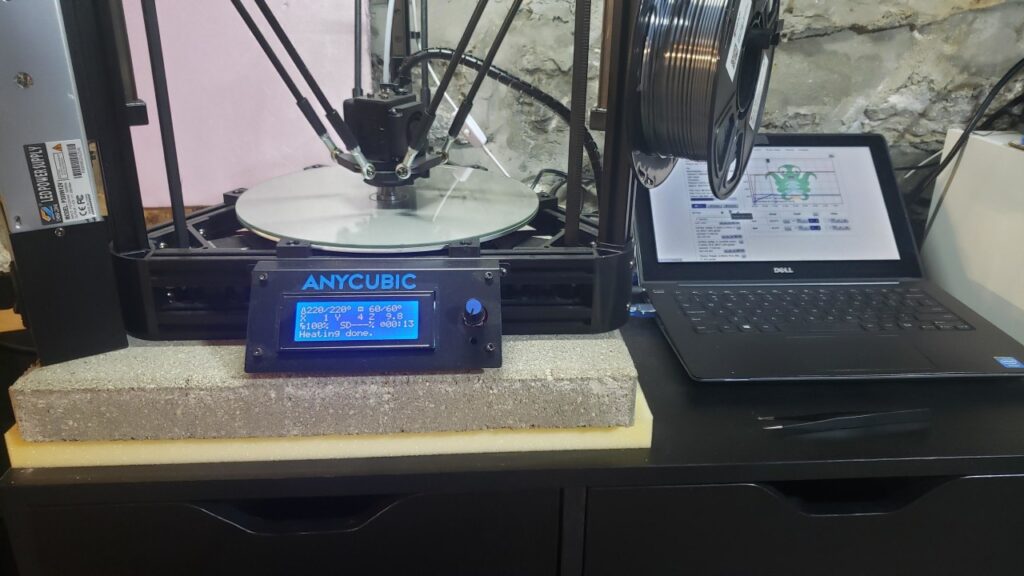

I’m finally getting less-incompetent with FreeCAD. Straight to “Part Design” workbench, sketch only one extruded pads’ features at a time, then decorate in any chamfers etc. at the interfaces. Import into PrusaSlicer with some sane defaults, send to the Anycubic Linear Kossel in the basement via OctoPrint (No, I don’t do it blind, I send and load the file, then go down to keep an eye on the startup sequence and make sure the filament hasn’t cracked and such), receive part.

Fit is intentionally a bit loose on all dimensions, nothing this part interacts with is consistent or close-tolerance, everything should move if it wants to, and the chamfer gets the tube seated well enough to not flop about.

FCStd and 3mf if anyone else happens to have this exact problem, which seems likely because similar thread assortments seem to be pretty ubiquitous on the usual eCommerce sites.