I’ve been doing some component stocking lately, and haven’t really set up a solid storage system, so I picked up a Harbor Freight 40+1 drawer cabinet thing to manage various small size + small quantity parts.

There are slots in the drawers to take dividers, but Harbor Freight doesn’t sell them, and Akro-Mils charges a bit much – somewhere in the vicinity of $10/16pcs – for injection molded dividers that experience says don’t fit terribly well. The set of Akro-Mils drawers I use on campus for kitting out instructional labs has first-party dividers that tend to float just enough to get pins trapped under them, which leaves me less than enthusiastic about spending money on those.

I saw some folks 3D Print their own, but always feel silly 3D printing flat parts, and wanted something clear.

..So I took some measurements, ordered some 0.078″/2mm polycarbonate sheet, and CAD’d up the shape.

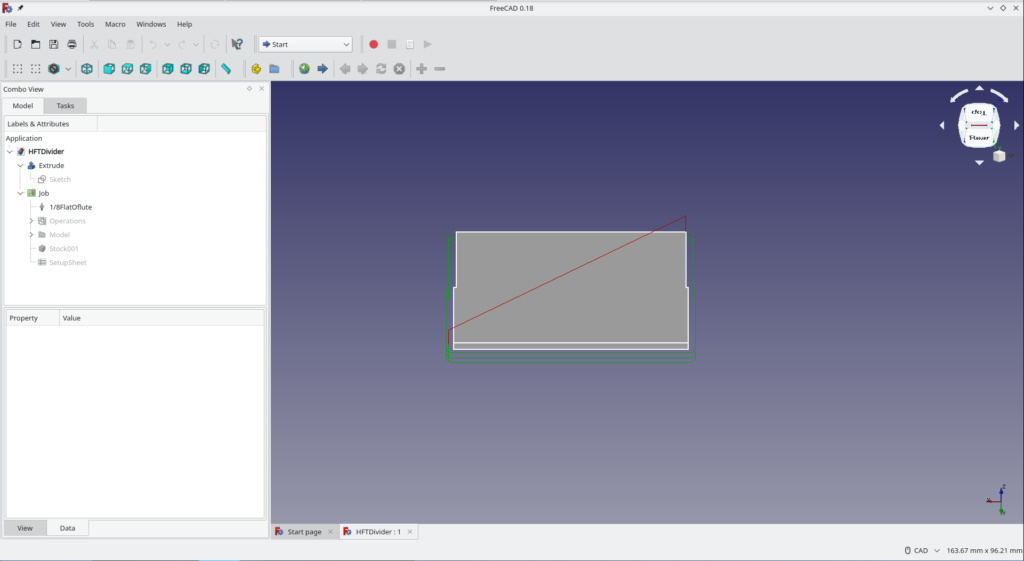

I did a quick parametric sketch/extrude/profile in FreeCAD 0.18, and unlike the last couple times I tried to build something in FreeCAD, the Sketch constraint system didn’t bug out, the Path workbench didn’t crash, and it posted reasonable gcode. I am very pleased by this development.

Now, it is a trivial part (rectangular, 2mm thick, 34mm tall, 50mm wide for the bottom 17mm, 51mm wide for the top 17mm), but I had earlier versions of FreeCAD fall over on similarly-trivial projects, usually in the path workbench. I’d really like to have (and be vaguely competent at using) a decent all-FOSS design flow for the router, so this is an exciting development. File here if anyone wants it.

There was the usual CNC fuckery (losing Z steps because I plunged too aggressively for the bit, tapping the Z- stop because I had the spindle raised in its clamp for working off a vise and forgot, etc.), some of which were solved by finally switching my Z axis motor to a slightly higher current since I keep having problems with running out of Z force.

Had I looked a little closer I would have noticed there are third party laser-cut acrylic dividers available for like $0.33/ea compatible with the Akro-Mils small drawer size, but if you ignore the …$1000-odd of CNC machine and tooling and the value of my time… these come out to like $0.16, so it’s not completely absurd from that angle, and it was a good tool-chain test. Also, happily, they fit significantly tighter than the Akro-Mils injection molded ones, so no trapped pins.