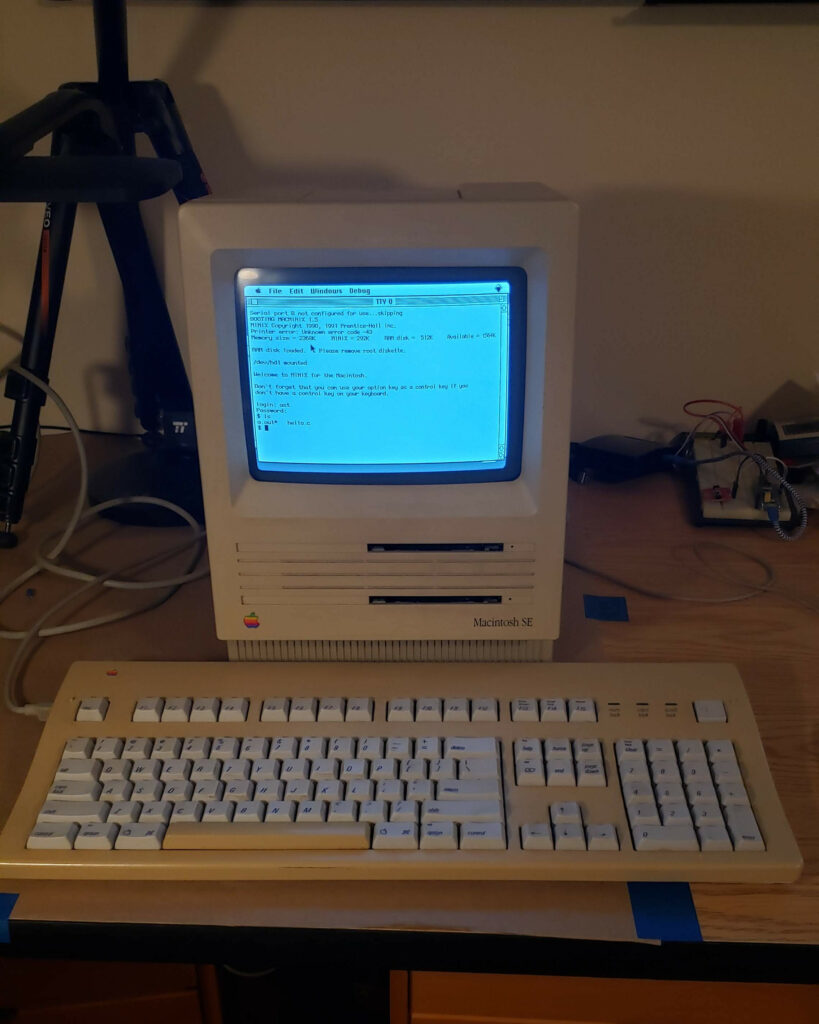

I had my dear old Macintosh SE out for a health check as I slowly extract my vintage computer collection from the (unconditioned) place I’ve been keeping it at my parents house to the basement of the place I’m renting. It had a couple interesting findings that seem worth putting online, including another floppy drive rebuild and a slightly elaborate fan replacement.

This particular machine is an early M5010 (Shipped with dual 800k floppy drive, 1MB of ram, squirrel cage fan; If I’m interpreting right the S/N indicates 9th week 1987) SE. I’m rather attached to it, but not because it’s particularly pristine (it’s not), because it’s convenient (800k floppy controller is a significant liability vs. 1.44), or for any long history. It was a yardsale find in the early 2000s rather than a machine I owned when it was relevant; I think I like it so much because it’s very close to my own age.

It has, over the years, been maxed out without doing anything grossly period-incorrect; 4 whole MB of RAM, an 80MB SCSI hard drive 1 installed on its side wrapped in a piece of insulating paper in the spot beside the drive cage and below the CRT where many SEs had a HDD wedged, and the soldered-in PRAM battery has been clipped out to prevent the typical murder/suicide situations. One of these days I’ll get around to installing a holder, but I don’t really care that it doesn’t save settings. Sadly, it also had some broken fan blades in the squirrel-cage that made it rattle horribly, so it had been disabled and ran fanless for a few … decades… until I got around to grafting a 65mm in there (see below).

I think the primary thing I’ve done with the SE is play with MacMinix, which I installed sometime in the early 2000s from the 1.5.10.7 image for HDD based installs that appears to be the only version on the modern net. I have never seen or heard of extant copies of the 8x800K floppy distribution with manual ( 0-13-585050-9, $169 at the time) the documentation and period sources talk about, but would really like to.

I’ve actually learned useful things about how UNIXes are put together from looking at Macminx 1.5; it’s a slightly feeble V7-like with almost full source, and was designed as an educational tool (MINIX 1/2 exists as a companion to Andrew S. Tanenbaum’s “Operating Systems: Design and Implementation” textbook), so it looks more or less like a “normal” UNIX, but is incredibly simple and easy to poke through if you want to figure out how something is fundamentally done. One of these days I’ll get around to wrestling the online man pages 2 and a few other well-known aftermarket improvements into the MacMinix image(s).

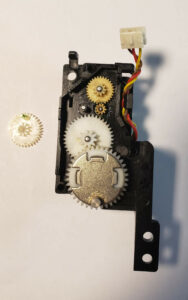

The gear that always breaks (top + pieces on removed gear) has broken

Motor pads to test without reassembly/computer.

During its 2017 health check I discovered the floppy drives had gone out, and fixed them by diassasembling, cleaning, re-lubing, and installing one of the 3D printed replacement gears from Vesperworks via Shapeways in one. That exact design is apparently no longer available, but I see them from other vendors. Those gears a golden age of retrocomputing piece of space magic – every Sony/Apple 3.5″ floppy drive has one failure-prone gear in the disc handling mechanism, and until affordable 3D printing they were irreplaceable. You can’t reliably do that kind of fine-pitch gear on an FDM printer, but it’s easily in the reach of SLA machines, so all the time bombs are defused.

This time the second 800k floppy drive required gear replacement. A noteworthy thing I’ve never seen mentioned elsewhere is that there are two large easy-to-reach pads for the motor leads that you can apply 5V to (ideally +5 on the top/red wire pad and Gnd on the bottom/black wire pad, but it doesn’t seem to hurt it to reverse) to test the mechanism without fully reassembling the drive and connecting it to a host.

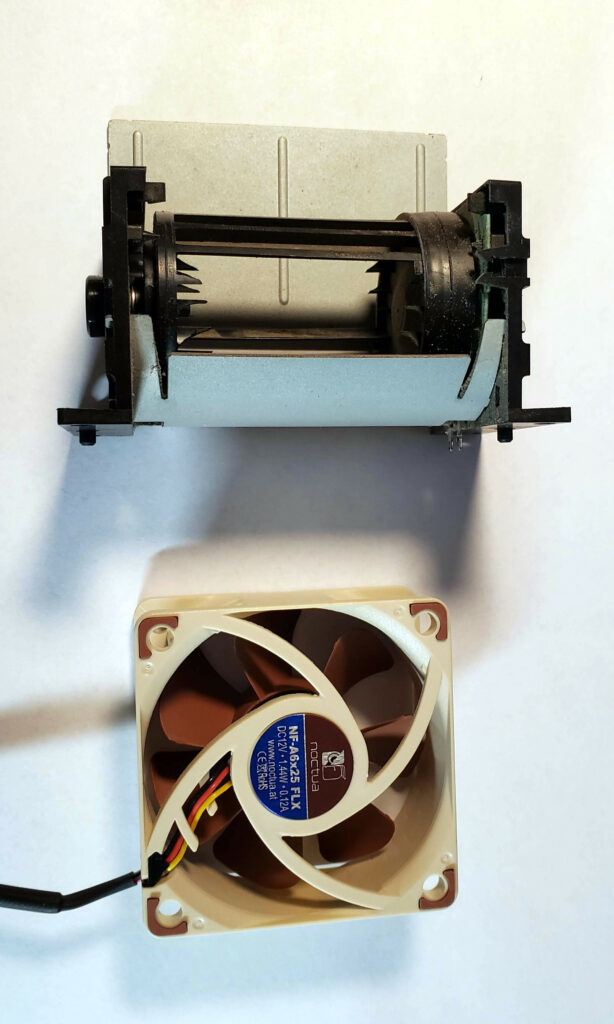

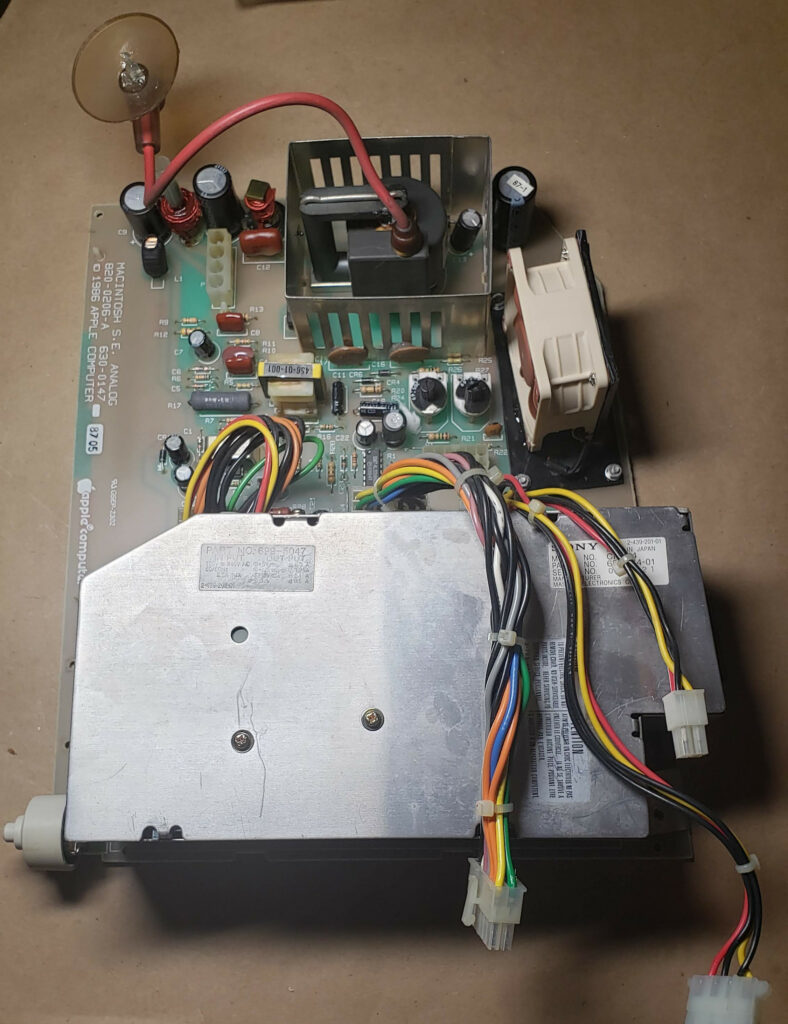

I also had a scare with the SCSI bus (turned out to be a loose cable, all is well) and pulled the analog board to check for a bad output cap on the +12VD line while I was diagnosing it. Since I had the board out, it seemed like high time to install the replacement fan I bought for it in ..2017. I’m using one of the Noctua NF-A6x25 65mm fans that are recommended various places for SE and similar compact Macs, and I fully concur with the suggestion, it fits perfectly, gives excellent airflow, is essentially silent, and even visually fits in.

Old broken blower, new Noctua NF-A65x25. Obviously not quite drop-in.

Transfer punches, Plastic knife, Carbide scribe, plastic stock, and blower lined up.

Footprint for SE analog board fan assembly, with polarity marked.

New fan mounting base plate, with holes and and drill. This is the critical part.

Old squirrel cage blower, completed replacement fan assembly.

New fan installed on analog board.

Completed SE analog board with modern fan. Don’t power this thing without a motherboard, it won’t work right and you’ll possibly have 10kV on the anode cap.

Top view of my open but fully assembled SE in current condition. Replacement fan, SCSI HDD tucked next to drive cage in insulating wrap

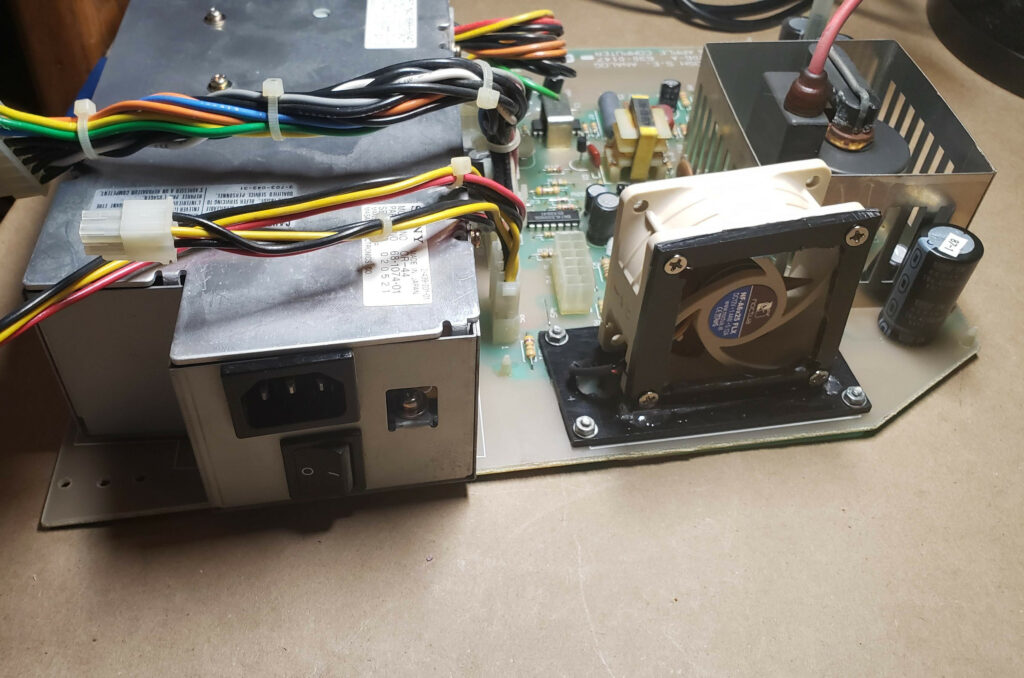

I did have the problem that because my SE is an early model with an awful squirrel-cage blower, I don’t have a bracket for a normal fan. Getting said brackets on the Internet tends to be expensive. So, as the owner of a 3D printer and CNC router I naturally… built the adapter entirely with hand tools. After I pulled the blower I realized I could just transfer its base plate dimensions and hole pattern onto a sheet of plastic (I used 1/8″ Acetal, HDPE would also be fine, I found my Acetal first), cut and drill it from the marks, and be done without a bunch of modelling and set-up.

I built my bracket with a second vertical plate to screw the fan into, but it felt a little less solid than I hoped, so I went ahead and epoxied the fan to the base plate as well. In retrospect, I should have just skipped the upright and gone directly to epoxying the fan to the plate. Some notes on building the adapter:

- If you work with plastic sheet goods, you owe it to yourself to get a proper plastic scoring drag knife, I’ve had one of these OLFA PB-800 holders for a couple years and it is absurdly better than a box cutter. Start it along a straight edge, a few passes for score-and-snap, or with a little patience you can cut with it by making more passes.

- Manual hand drills are cheap and enormously more tactile than power drills, the extra control makes not melting or cracking plastics way easier.

- Even for hand drilling, if you’re transferring with punches, spot drill before you drill. I missed one and tried to drill without and it was much uglier

- Just as many people suggest a sheet of insulation foam for putting under things you circular saw, foam makes a great backing for all kinds of cutting and drilling, especially in softer materials.

And with that, my SE is back to full function. Yes, there is a mile of unnecessary extra SCSI cable coiled up behind the hard disc, it’s been that way for ages, I’ll fix it if I ever want to put a PDS card in. Yes, the case has some increasingly-evident yellowing that I could peroxide bleach out, but it’s only cosmetic, compact Macs require somewhat invasive disassembly to bleach, and the machine spends most of its time under a cover anyway. But it’s entirely functional for a period-correct machine, and not experiencing any unnecessary degradation.

I’ve been having some fun talking to newer machines via a Mini-DIN-8 to DE-9 cable and various serial adapters, and a ZiModem I knocked together to try, but that is a separate post.

Notes:

1. You could buy the SE with 20MB or 40MB HDD and one floppy from the factory; Apple was selling 80MBs in the Mac II at the time, so close enough to period.

2. The real, commercial Prentice Hall MacMinix distribution didn’t include online man pages, you got dead trees. The dominant man system used on it was apparently set up by Warren Toomey of TUHS fame in the early 90s, when it wasn’t historical. He was quite active on comp.os.minix and maintained a FTP server for Minix stuff out of the Australian Defense Force Academy in the early 90s.