Another bit of progress on the CNC project: Better drive nuts!

The design is attempting to avoid expensive, difficult-to-source, or chicken-and-egg problem machined parts. The biggest issues because of that policy come from the couplers which attach the lead screws to the motors, and the drive nuts which attach the axes to the lead screw. Because my leadscrews are 3/8-16 Unified Coarse thread, there isn’t a “proper” solution to the problem, as any professional mill would be using Acme or Ball threads for the leadscrews. Therefore it has been hobby engineering all the way on those parts.

The current couplers (with which I am becoming ever more unsatisfied; they slip badly on direction reversals) are constructed by seizing a 3/8” coupling nut onto the end of the rod, drilling a 1/4” hole through the rod/nut assembly, and drilling and tapping a hole for a set screw into the side of the nut to grab the flat of the motor shaft. Because the frame won’t accommodate Lovejoy-type couplers (the canonical solution for such things), I suspect the eventual replacements may look something like the nested fuel line couplers this and other similar designs employ. I don’t like the lack of stiffness in those configurations, but things don’t appear to be tightly enough aligned for the inflexible couplers, and the slippage problem will be a show-stopper for actually milling with it.

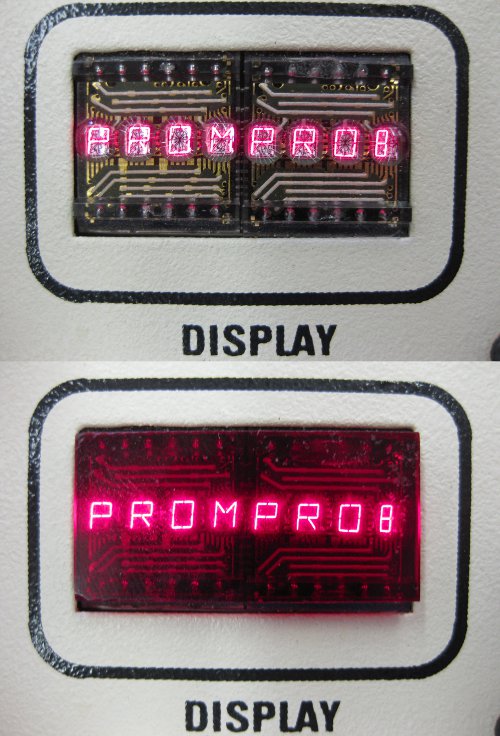

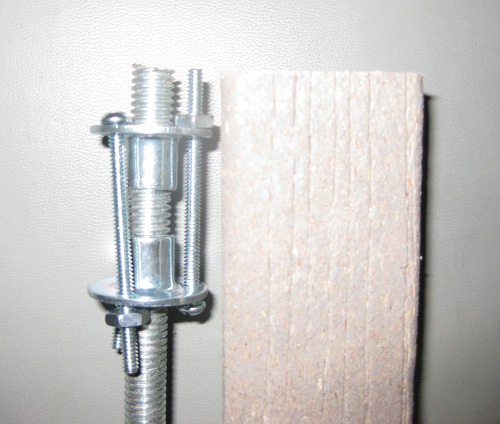

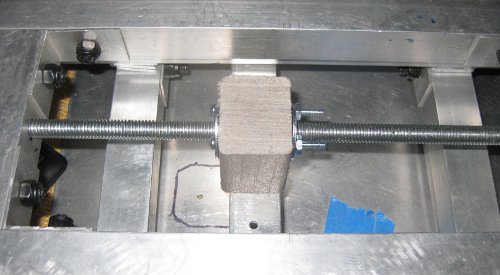

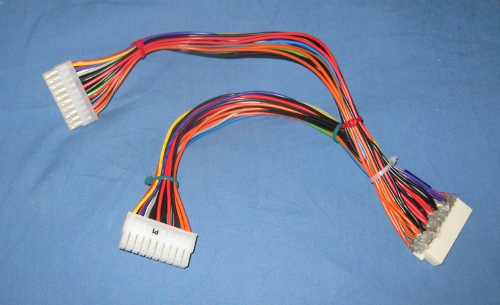

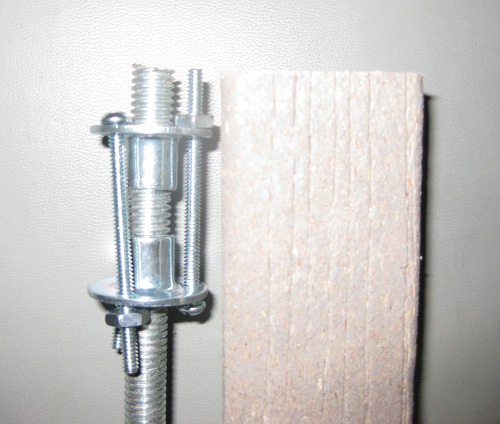

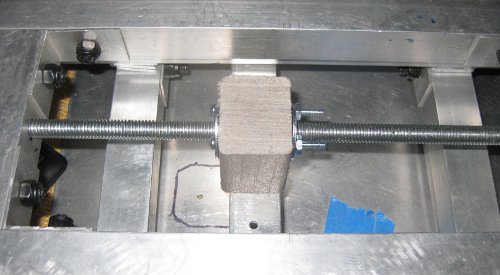

The old solution for the drive nuts was roughly-bent steel brackets, wrapped around coupling nuts. The theory was that the steel would be springy enough to pull things into alignment, and malliable enough to beat, bend, twist, or otherwise adjust the fit. In actual fact, no amount of adjustment could get them to align perfectly, and the springiness wasn’t enough to prevent them from contributing to the axes walking in their rails. That design was eventually abandoned, and no good alternative came to mind, so one of my collaborators and I performed one of the best techniques for mechanical problem solving; we wandered around a home improvement store until we found parts to make something that would work. The solution? — Pairs of Tee nuts (the kind with screw holes, not tacks), attached together with machine screws (adjusting the tightness of the screws controls the preload, which gives free anti-backlash effects), mounted in blocks of Trex (A plastic/wood fiber composite material), which is cheap, easy to obtain, and works similarly to HDPE (Which is to say, wonderfully. Think soft, forgiving wood with no grain). These seem to be better than the old ones, and (possibly with a bit of shimming) workable for a usable mill.

Check out deez nutz:

Rough-fit Outside the block (that is a bar of Trex stock next to it):

and one nut complete and sitting in place:

There is a fair amount of fiddly fitting and drilling to putting those together, but nothing too awful. The machine screws have been trimmed and the edges of the block dressed a bit with a file after the other one went together, so they look pretty solid. In addition to better nuts, the other good discovery is that I suspect that Trex will make excellent, low cost, easily available material to mill objects without any particular material constraints from once the machine is working, I just wish it didn’t have tacky looking faux-woodgrain molded into the stock.