I’m posting this because it’s such a nice example for the standard “What are 3D printers really good for?” question.

When I got to the lab today, I was told the can chute in our mini-fridge was broken. Inspection showed that too many of the little plastic inserts/bushings that retain the bars were missing and/or broken. This is a years-old cheap GE minifridge, so it isn’t even worth looking for OEM replacements.

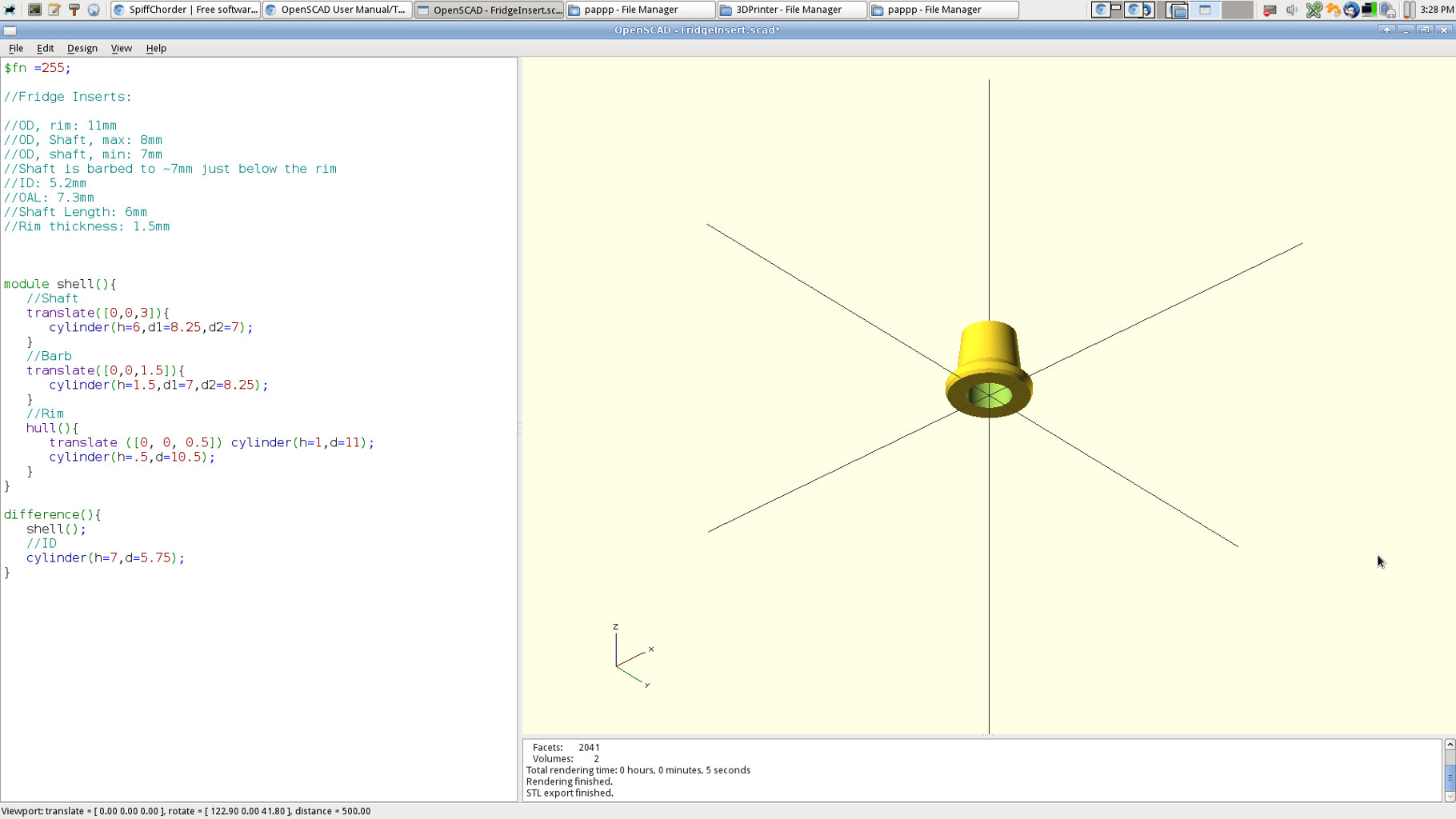

Now we get to the “Thinking with 3D printing” part: I plucked one of the remaining ones, went over it with some calipers, transferred the measurements into OpenSCAD, and printed one off to test fit. The ID was a little tight, so I adjusted the model, printed 6 more, and fixed the problem.

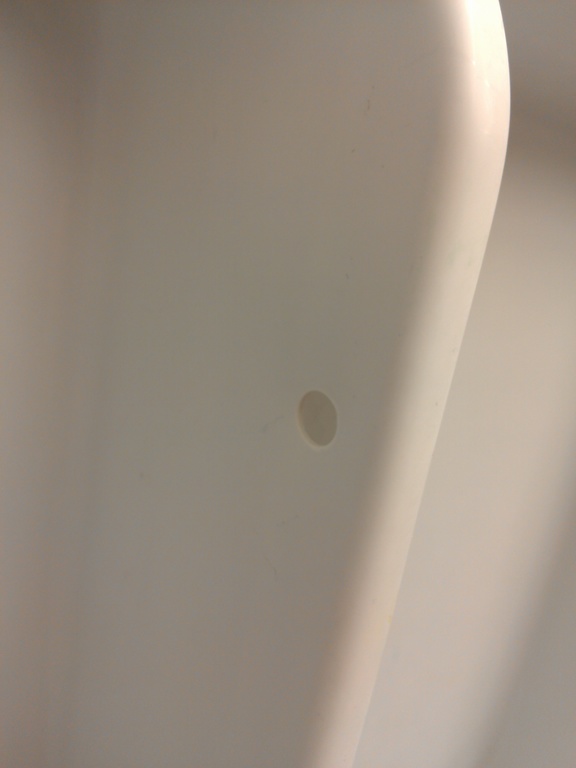

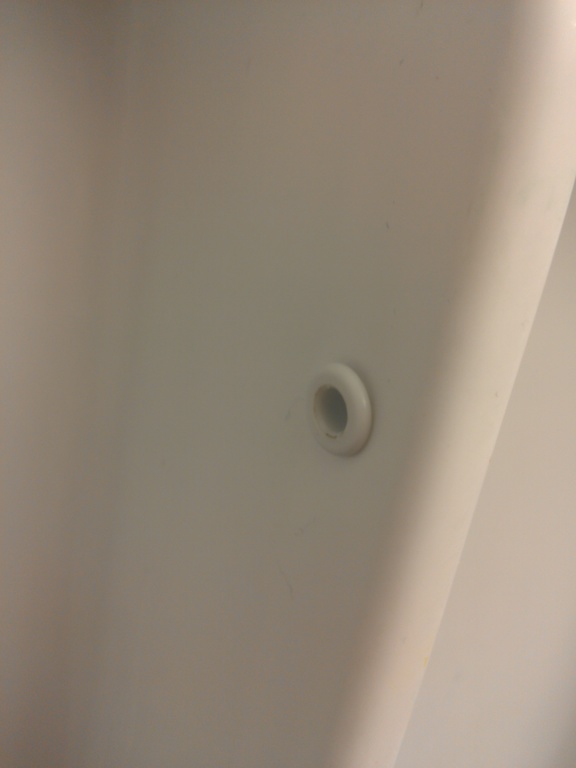

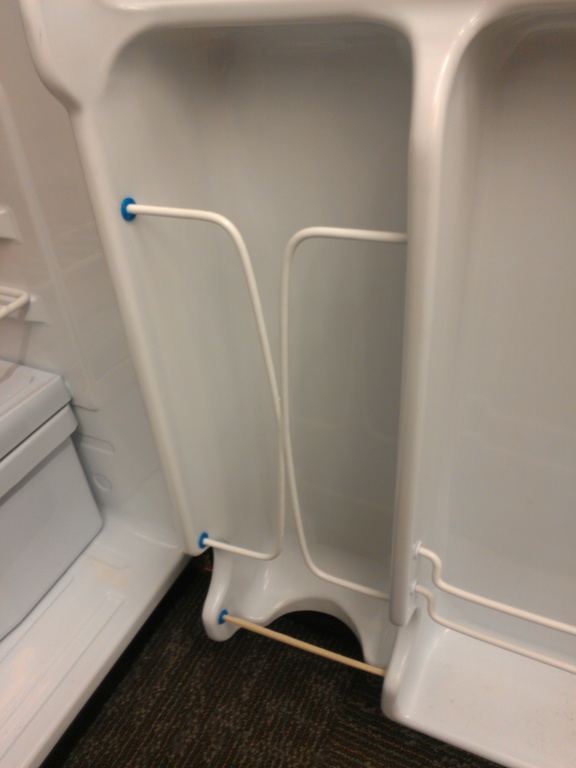

- The lab fridge’s can chute fell apart, because the little bushings that hold the retainer died.

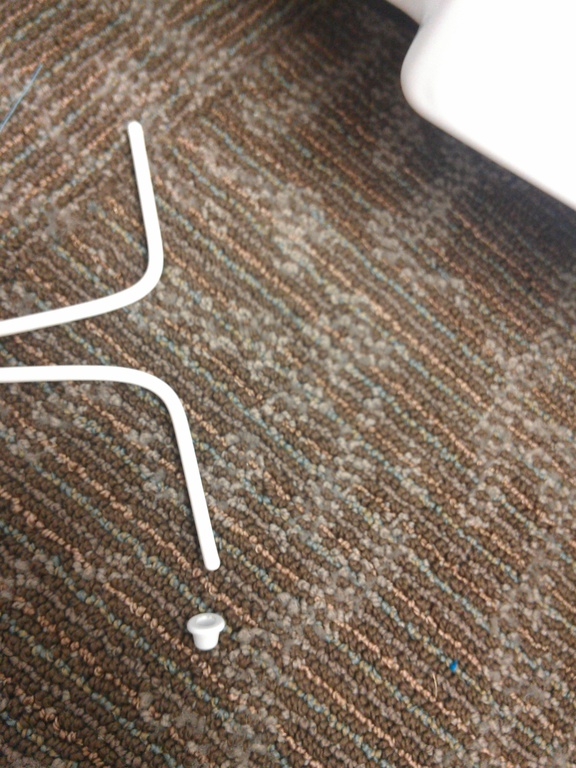

- Rack with intact bushing on the floor.

- Bushing installed properly. They’re sort of loose.

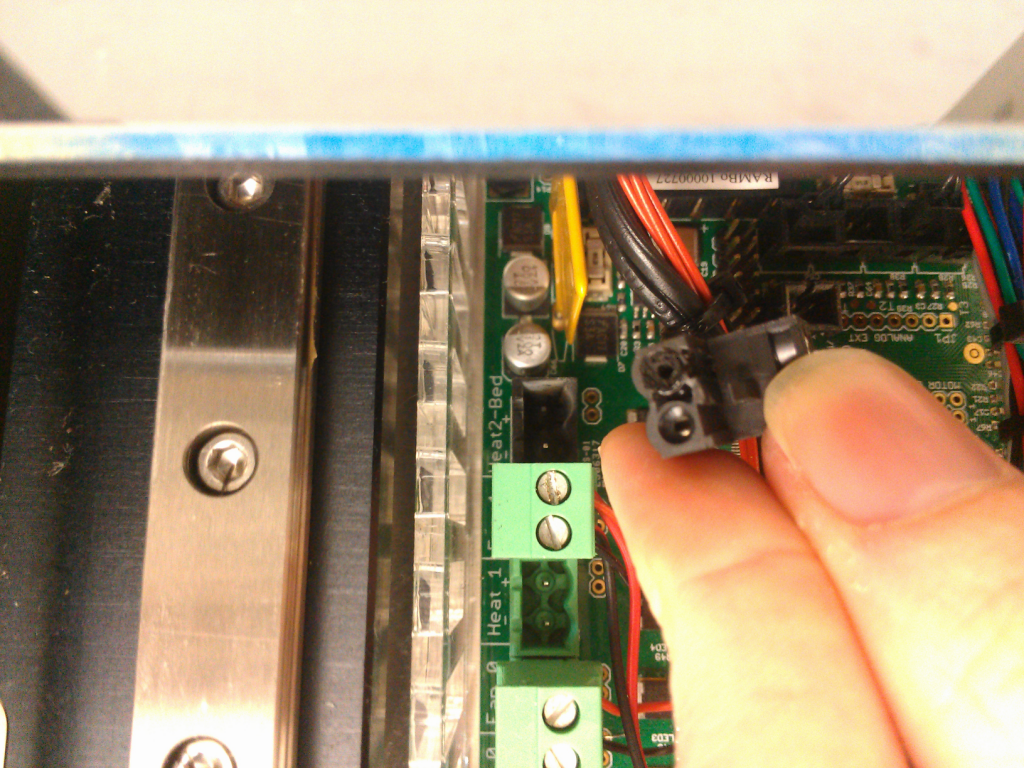

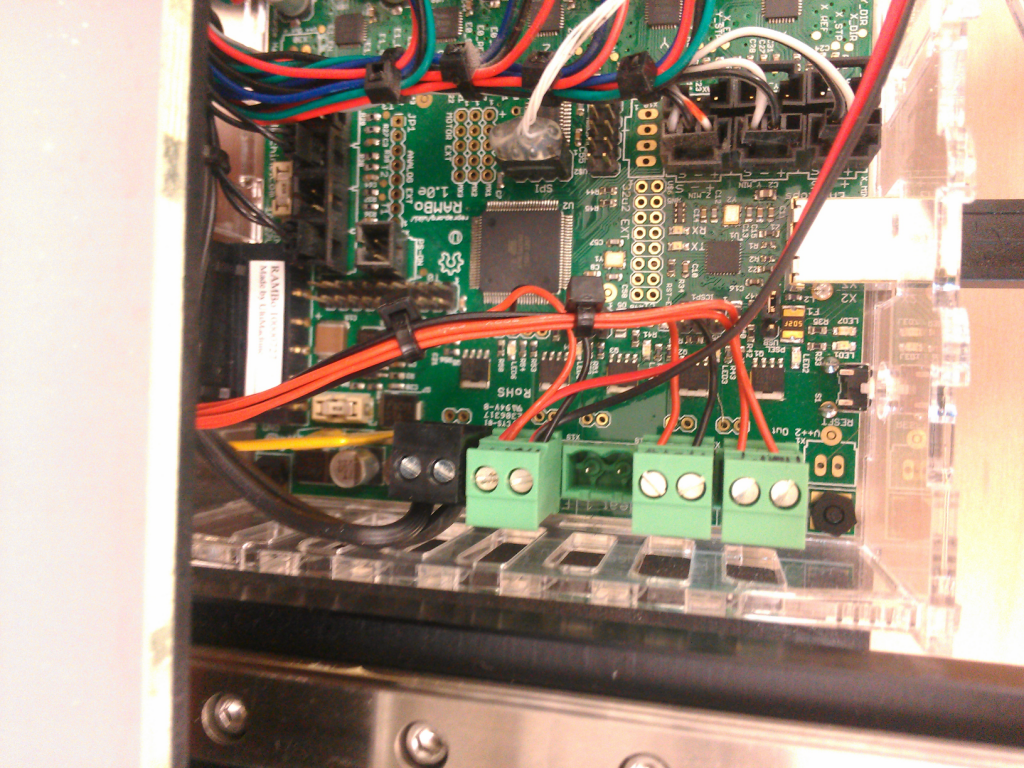

- Grab some calipers and describe the bushings to OpenSCAD.

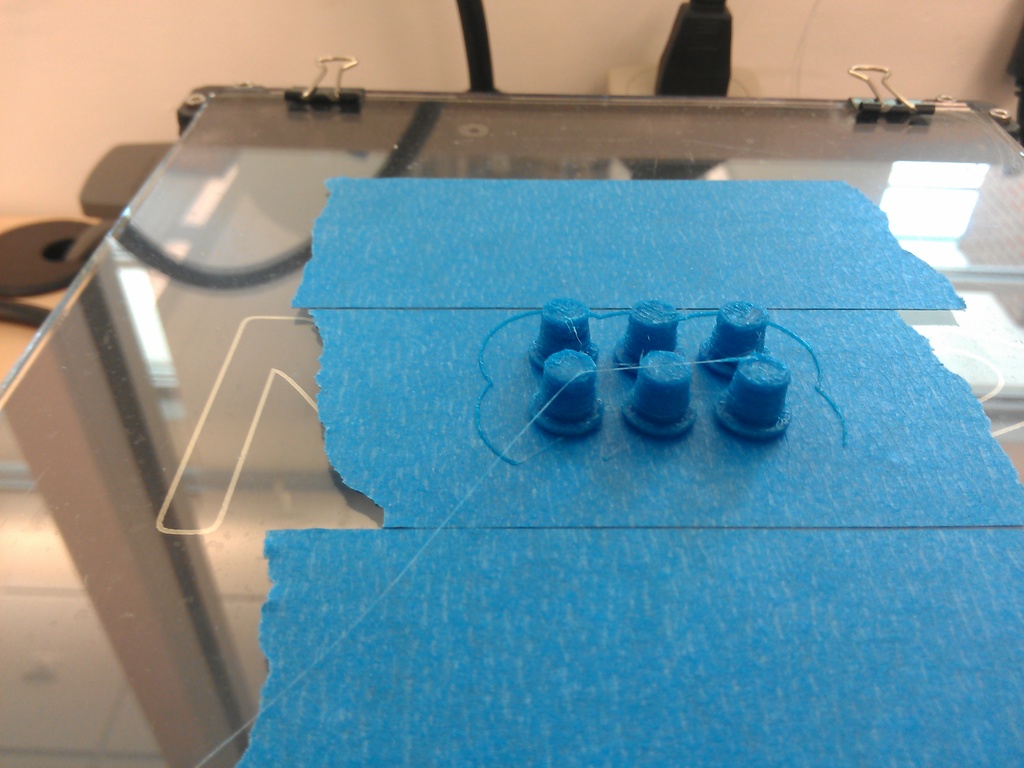

- Pass the model through Cura and the M2 to get a test fit. Slightly too tight on the ID.

- Iterate model, print 6.

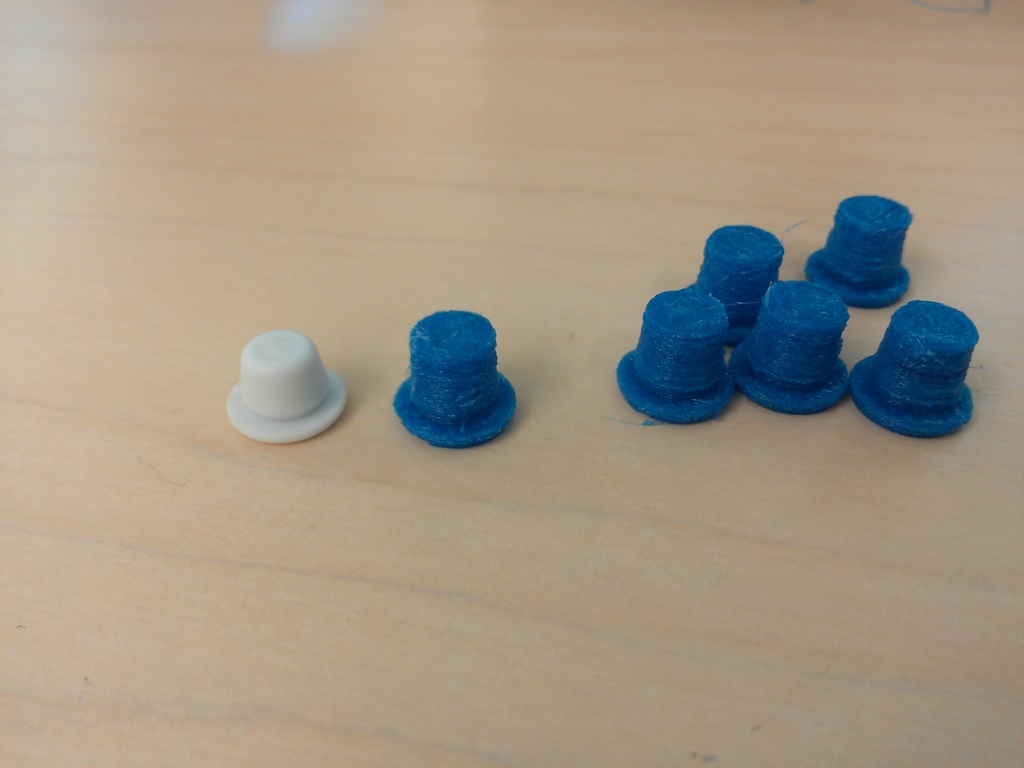

- OEM and Custom comparison. Made them a little bigger.

- ID looks cleaner on the ones that were printed in a group, more cooling between layers.

- And fixed. Note also the awesome retention bar made out of a chopstick from a previous repair.

In case the model is useful for anyone else: OpenSCAD and STL.

Important Details:

- This took like an hour from start to finish, and wasn’t the only thing I was doing at the time. The printing itself was around 1 minute per insert.

- The new inserts are better than the originals. Not quite as pretty in some ways (though they are blue and glow-in-the-dark, because that’s our current junk filament), but the fit is considerably better.

- That “iterate” step in the middle, where you just try it and adjust if needed is among the most beautiful things about 3D printers.